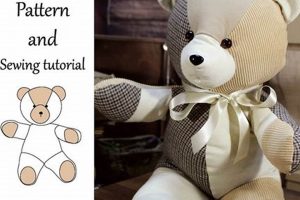

A plan or blueprint for creating a soft toy bear involves instructions and diagrams detailing the shapes, sizes, and assembly methods required. These resources can range from simple designs for beginners to complex, articulated creations for experienced sewers. Typically, they specify fabric types, stitching techniques, and stuffing materials. A well-drafted plan results in a consistent, predictable final product.

These blueprints empower crafters to personalize handmade toys. They provide a foundational framework, enabling adjustments to size, shape, and features to create unique and cherished gifts. The availability of these plans democratizes toy making, allowing individuals to produce professional-quality items regardless of their sewing expertise. Historically, the dissemination of such plans has contributed significantly to the enduring popularity of handmade toys, providing continuity across generations and preserving traditional crafting skills.

Understanding the components and utility of such a plan is essential for anyone interested in crafting stuffed animals. The following sections will delve into fabric selection, stitching techniques, and assembly best practices.

Tips for Utilizing Teddy Bear Sewing Plans

Careful consideration of several factors ensures successful project completion when working with soft toy bear construction plans. These tips offer guidance for both novice and experienced crafters.

Tip 1: Fabric Selection: Opt for durable, washable fabrics suitable for frequent handling. Closely woven cotton or plush materials are recommended. Fabric choice impacts both the final appearance and the toy’s longevity.

Tip 2: Accurate Cutting: Precise cutting of pattern pieces is crucial for proper assembly. Sharp scissors and careful adherence to pattern markings ensure correct component dimensions and minimize seam allowances.

Tip 3: Seam Allowance Consistency: Maintaining uniform seam allowances prevents fit issues during assembly. Consistent seams contribute to a polished, professional finish.

Tip 4: Proper Stuffing Technique: Distribute stuffing evenly to achieve the desired shape and firmness. Overstuffing can distort the toy’s appearance, while understuffing may result in a limp, unappealing form.

Tip 5: Secure Closures: Utilize strong, hidden stitching for closures to prevent seam separation and ensure the toy’s structural integrity. Secure closures contribute to the toys safety and durability.

Tip 6: Embellishment Choices: Embellishments like embroidered features or safety eyes should be added securely and appropriately for the intended age of the recipient. Safety considerations should always be paramount.

Adherence to these guidelines ensures a successful crafting experience and yields a well-constructed, durable, and aesthetically pleasing finished product. These principles contribute to a satisfying crafting process and a cherished handmade toy.

By following these recommendations, crafters can create heirloom-quality toys that provide lasting enjoyment.

1. Design

Design serves as the foundational blueprint for a stuffed teddy bear pattern. It dictates the bear’s final form, influencing its proportions, posture, and overall aesthetic. A well-conceived design considers the intended purpose of the bear, whether it’s meant to be a cuddly companion for a child or a decorative display piece. This pre-planning stage determines the complexity of the pattern, affecting construction techniques and material choices. A simple design might feature basic shapes and minimal seams, while a more complex design might incorporate articulated limbs, intricate detailing, and advanced sewing techniques. The design stage also considers the incorporation of unique features, such as embroidered details or clothing items, further personalizing the finished product. For instance, a teddy bear intended for a baby might prioritize safety and simplicity, leading to a design with embroidered features rather than button eyes.

A robust design anticipates potential construction challenges and provides solutions within the pattern itself. Careful consideration of seam placement, fabric choice, and stuffing techniques during the design phase ensures a smoother construction process and a more durable final product. A pattern designed for beginners might incorporate larger seam allowances and simpler shapes to facilitate ease of construction. Conversely, a pattern designed for experienced sewers might involve complex curves and intricate joining methods to achieve a more sophisticated result. Consider a teddy bear designed with elongated limbs; the design would need to account for the weight distribution and ensure the bear can maintain balance, perhaps by incorporating weighted elements in the feet.

Understanding the integral role of design in a stuffed teddy bear pattern enables crafters to approach projects with greater foresight and control over the final outcome. A thorough design minimizes potential issues during construction, streamlines the sewing process, and ultimately contributes to a higher quality, more satisfying finished product. Effective design provides the framework for translating a creative vision into a tangible, cherished object.

2. Fabric

Fabric selection significantly impacts the final appearance, feel, and durability of a stuffed teddy bear. The chosen material influences not only the bear’s aesthetic qualities but also its longevity and suitability for its intended purpose. Understanding the characteristics of different fabrics is crucial for successfully executing a stuffed teddy bear pattern.

- Durability:

A teddy bear’s fabric must withstand regular handling, particularly if intended for a child. Durable fabrics like tightly woven cotton, canvas, or plush materials are preferred for long-lasting toys. A delicate silk or linen, while aesthetically pleasing, would be less suitable for a child’s toy due to its susceptibility to tearing and wear. Choosing a durable fabric ensures the finished product withstands the rigors of play and remains a cherished companion for years to come.

- Texture:

Texture contributes significantly to the tactile experience of a teddy bear. Soft, plush fabrics like minky or faux fur offer a comforting feel, while corduroy or textured knits provide sensory interest. The chosen texture influences how the bear is perceived and interacted with. A smooth, velvety fabric might convey luxury and sophistication, while a nubby or textured fabric might offer a more rustic and playful appeal. Fabric texture should align with the intended design and purpose of the teddy bear.

- Aesthetics:

Fabric color and pattern contribute to the bear’s overall visual appeal. Solid colors offer classic simplicity, while prints and patterns add personality and visual interest. Consider a teddy bear intended for a baby; pastel shades or gentle patterns might be more appropriate than bold, contrasting colors. The aesthetic qualities of the fabric should complement the design and intended recipient of the teddy bear.

- Maintenance:

Practicality is a key factor in fabric selection, especially for children’s toys. Washable fabrics simplify cleaning and hygiene maintenance. Choosing a fabric that can be easily laundered ensures the bear remains clean and fresh. Certain fabrics, such as wool or silk, may require specialized cleaning, making them less practical for frequently handled toys. The ease of cleaning and maintaining the chosen fabric should factor into the decision-making process.

The interplay between fabric characteristics and the stuffed teddy bear pattern itself is crucial. A well-chosen fabric enhances the design, contributes to the bear’s overall appeal, and ensures its longevity. Careful consideration of these factors results in a finished product that is not only aesthetically pleasing but also durable and fit for its intended purpose, whether as a cherished childhood companion or a decorative piece.

3. Seams

Seam construction constitutes a critical element within a stuffed teddy bear pattern, significantly influencing the final product’s structural integrity, aesthetic appeal, and overall durability. Proper seam selection and execution are essential for achieving a well-crafted, professional-looking finished product. The following facets highlight the importance of seams within this context.

- Seam Type:

Different seam types offer varying levels of strength and visual appeal. Common choices for stuffed animals include the backstitch, renowned for its durability, and the ladder stitch, ideal for closing openings discreetly. Selecting the appropriate seam type for different parts of the bear impacts its overall strength and finish. A backstitch, for example, reinforces high-stress areas like leg attachments, whereas a ladder stitch creates an almost invisible closure along the back seam. Seam type selection depends on the specific requirements of each section of the pattern.

- Seam Allowance:

The seam allowance, the fabric width between the stitching and the raw edge, impacts both the final size and the durability of the finished bear. Consistent seam allowances are crucial for maintaining the intended proportions and preventing structural weaknesses. A narrow seam allowance might compromise the toy’s strength, while an excessively wide allowance can result in an unintended reduction in size. Accurate adherence to the pattern’s specified seam allowance ensures the finished product conforms to the intended design.

- Seam Finishing:

Techniques such as pinking shears or serging prevent fraying and enhance seam durability, particularly important for frequently handled toys. Proper seam finishing contributes to a professional appearance and extends the lifespan of the finished product. Unfinished seams can unravel over time, compromising the toy’s structural integrity. Seam finishing techniques provide essential reinforcement, especially in areas prone to wear and tear.

- Seam Placement:

Strategic seam placement minimizes bulk and maximizes aesthetic appeal. Careful consideration of seam lines during the design phase ensures a smooth, even finish. For example, placing seams along natural contours or less visible areas minimizes their visual impact. Thoughtful seam placement contributes to a more polished, professional final product.

Understanding the interplay between seam construction and the overall stuffed teddy bear pattern is essential for creating a well-crafted, durable, and aesthetically pleasing finished product. Proper seam selection, precise execution, and appropriate finishing techniques contribute significantly to the toy’s longevity and overall quality, transforming a simple pattern into a cherished keepsake.

4. Assembly

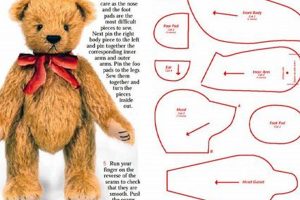

Assembly represents the crucial stage where the two-dimensional blueprint of a stuffed teddy bear pattern transforms into a three-dimensional object. This process involves a methodical approach, adhering strictly to the pattern’s instructions to ensure accurate construction. The pattern typically dictates the order of component assembly, outlining which pieces to join and the specific sewing techniques required for each connection. For example, the pattern might instruct joining the head pieces before attaching them to the body, followed by limb attachment and finally, closure of the remaining opening for stuffing. This structured approach minimizes errors and ensures symmetrical results. The quality of assembly directly impacts the final product’s structural integrity, aesthetic appeal, and overall durability. A well-executed assembly results in a sturdy, symmetrical, and visually appealing teddy bear, while a flawed assembly can lead to structural weaknesses, asymmetry, or an unprofessional finish.

The assembly phase requires careful attention to detail. Pinning fabric pieces accurately before stitching ensures proper alignment and prevents unintended shifts or puckering. Matching notches marked on the pattern pieces guides precise joining, contributing to a symmetrical finished product. For instance, aligning notches on the head pieces ensures the ears are positioned correctly and the facial features are centered. Choosing the appropriate stitching technique for each step is crucial. A strong backstitch secures load-bearing seams like leg attachments, while a hidden ladder stitch closes the final opening discreetly. Understanding and applying these techniques contributes to a polished, professional finish. Failure to adhere to the specified techniques can lead to weakened seams or visible stitching, compromising the toy’s durability and aesthetic appeal.

Mastering the assembly process translates a flat pattern into a tangible, three-dimensional form. The precision and care applied during this stage directly influence the final product’s quality. A meticulous approach ensures the stuffed teddy bear aligns with the pattern’s design intent, resulting in a well-constructed and aesthetically pleasing finished product. Ultimately, successful assembly hinges on a clear understanding of the pattern instructions, precise execution of sewing techniques, and unwavering attention to detail throughout the construction process. This transforms individual fabric pieces into a cherished keepsake.

5. Embellishments

Embellishments provide the finishing touches that transform a basic stuffed form into a character-rich teddy bear. These details, strategically incorporated within the stuffed teddy bear pattern, contribute significantly to the toy’s personality and aesthetic appeal. From embroidered features to carefully chosen accessories, embellishments personalize the creation and enhance its overall design. Understanding their role and application is essential for crafting a truly unique and expressive teddy bear.

- Facial Features:

Eyes, noses, and mouths breathe life into a teddy bear. Options range from safety eyes and noses for children’s toys to embroidered features for a more handcrafted look. Material choices include plastic, glass, or embroidered thread. The selection of facial features establishes the bear’s personality and expression. Embroidered eyes, for example, might convey a gentler, more traditional aesthetic, while large, expressive plastic eyes might create a more playful and contemporary feel. These details significantly impact the bear’s overall character.

- Clothing and Accessories:

Small articles of clothing or accessories add personality and charm. A simple knitted scarf, a miniature hat, or a tiny backpack transforms a plain bear into a unique character. These additions create opportunities for storytelling and imaginative play. A teddy bear dressed as a sailor, for instance, invites nautical adventures, while a bear wearing a graduation cap celebrates academic achievement. Clothing and accessories enhance the play value and personalize the teddy bear.

- Embroidery and Appliqu:

Decorative stitching or fabric patches add intricate detail and visual interest. Embroidered floral patterns, personalized names, or appliqud shapes enhance the bear’s aesthetic appeal. These techniques allow for intricate customization. Embroidering a heart onto the bear’s chest, for instance, adds a touch of sentimentality, while appliqud paw prints add a playful element. Such details elevate the bear beyond a simple toy, transforming it into a personalized work of art.

- Hair and Other Textural Elements:

Adding yarn hair, felt patches, or other textural elements enriches the sensory experience of the teddy bear. These additions provide tactile interest and enhance the bear’s personality. A long, flowing mane of yarn hair might create a glamorous and sophisticated look, while short, fuzzy felt patches might convey a more playful and cuddly feel. Such details add depth and complexity to the teddy bear’s design.

The strategic incorporation of embellishments within a stuffed teddy bear pattern significantly elevates the finished product. These seemingly small details contribute significantly to the bear’s overall character, charm, and sentimental value. By carefully considering the choice and placement of embellishments, crafters can create unique, personalized teddy bears that resonate with individual expression and provide lasting enjoyment. From simple embroidered details to elaborate costumes, embellishments transform a basic stuffed form into a treasured keepsake.

6. Finishing

Finishing represents the crucial final stage in bringing a stuffed teddy bear pattern to life, encompassing the techniques that transform a sewn form into a complete, polished creation. These essential steps ensure structural integrity, enhance aesthetic appeal, and contribute to the overall quality and longevity of the finished teddy bear. A well-executed finish distinguishes a handcrafted item from a mass-produced product, adding a touch of artistry and care.

- Closure:

Closing the remaining opening after stuffing requires a discreet and secure method, typically a ladder stitch. This stitch creates an almost invisible seam, ensuring the stuffing remains contained while maintaining a smooth, unbroken surface. Properly executed closure contributes significantly to the finished product’s polished appearance. A poorly closed seam detracts from the overall aesthetic and may compromise the toy’s durability.

- Stuffing:

Achieving the desired firmness and shape requires evenly distributing stuffing material throughout the bear’s body. Overstuffing can distort the toy’s form and stress the seams, while understuffing results in a limp, unappealing appearance. Proper stuffing techniques ensure the bear maintains its intended shape and provides a satisfying tactile experience. Different stuffing materials, such as polyester fiberfill or wool roving, offer varying levels of firmness and resilience, influencing the final product’s feel and weight.

- Brushing and Shaping:

Brushing the bear’s fur or fabric nap smooths the surface and removes any stray fibers or wrinkles acquired during construction. This step enhances the toy’s visual appeal and provides a professional finish. For plush fabrics, a soft brush restores the pile’s direction and loft, creating a uniform and inviting texture. This finishing touch adds a layer of refinement to the completed teddy bear.

- Final Inspection:

A thorough inspection of the completed bear ensures all seams are secure, embellishments are firmly attached, and the overall construction meets quality standards. This final check identifies any minor imperfections requiring correction before the bear is deemed complete. This meticulous attention to detail guarantees a high-quality finished product, reflecting the care and craftsmanship invested in its creation. A final inspection reinforces the pride taken in handcrafted work.

The finishing techniques employed significantly impact the final quality and presentation of a stuffed teddy bear. These seemingly minor details contribute to the toy’s overall durability, aesthetic appeal, and perceived value. A well-executed finish elevates a handmade creation, transforming it from a simple sewn object into a cherished keepsake. The care and attention invested in the finishing stages reflect the dedication to craftsmanship and the desire to create a truly exceptional finished product. These final touches imbue the teddy bear with a sense of completeness and professionalism, ensuring it remains a treasured item for years to come.

Frequently Asked Questions

This section addresses common inquiries regarding stuffed teddy bear patterns, offering clarity and guidance for crafters of all skill levels. Understanding these key aspects facilitates a smoother construction process and contributes to a higher quality finished product.

Question 1: What fabric is best suited for a durable teddy bear?

Tightly woven cotton, canvas, or plush materials offer excellent durability for toys subject to frequent handling. Delicate fabrics like silk or linen are less suitable.

Question 2: How does seam allowance affect the finished product?

Consistent seam allowances are crucial for maintaining proper proportions. Inconsistent allowances can lead to sizing discrepancies and structural weaknesses. Adhering precisely to the pattern’s specified seam allowance is recommended.

Question 3: What techniques prevent seam fraying?

Pinking shears or serging provide effective seam finishing techniques, preventing fraying and enhancing the toy’s longevity. These methods minimize raw edge exposure and contribute to a more professional finish.

Question 4: What stuffing materials are commonly used?

Polyester fiberfill is a popular choice due to its affordability and resilience. Wool roving offers a firmer, more traditional feel. The choice of stuffing material impacts the final product’s weight, firmness, and overall tactile experience.

Question 5: What is the purpose of notches on pattern pieces?

Notches serve as alignment guides, ensuring accurate joining of fabric components. Matching notches ensures correct piece placement and contributes to a symmetrical finished product.

Question 6: How can embellishments be secured safely?

Embroidered features are generally safer than button eyes or other small attachments, especially for toys intended for young children. Securely anchoring any embellishments prevents detachment and potential choking hazards. Adhering to safety standards is paramount during the embellishment process.

Careful consideration of these frequently asked questions empowers crafters to approach projects with confidence and ensures a higher quality finished product. Understanding these key aspects contributes significantly to a successful and rewarding crafting experience.

The following section delves into advanced techniques for customizing stuffed teddy bear patterns, allowing for further personalization and creative expression.

Conclusion

Successful execution of a stuffed teddy bear pattern necessitates a comprehensive understanding of design principles, material selection, construction techniques, and finishing processes. From the initial design concept to the final embellishments, each step contributes significantly to the final product’s quality, durability, and aesthetic appeal. Careful consideration of fabric characteristics, seam construction, and assembly methods ensures a well-crafted, enduring toy. The strategic use of embellishments adds personality and charm, transforming a simple stuffed form into a cherished companion.

The enduring popularity of handmade teddy bears underscores the significance of these patterns as vehicles for creative expression and personalized craftsmanship. These patterns provide a framework for transforming simple materials into treasured keepsakes, imbued with individual artistry and sentimental value. The continued exploration and refinement of these patterns promise a future rich with handcrafted creations, each bearing the unique mark of its creator.