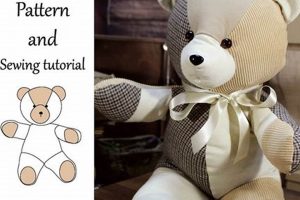

A design featuring stitched, often geometric, shapes applied to a soft toy resembling a bear involves a template or blueprint used for crafting. This template guides the creation of the toy, specifying fabric types, stitching methods for the decorative top layer, and assembly instructions. For instance, a template might depict diamond-shaped stitching across the bear’s body, requiring specific seam allowances and fabric cuts.

Such designs offer several advantages. The stitching adds a layer of textural and visual interest, enhancing the toy’s aesthetic appeal. The quilting technique can also reinforce the fabric, contributing to the toy’s durability and longevity. Historically, quilting has been a practical way to add warmth and strength to textiles, and its application to toys carries a sense of tradition and craftsmanship. These templates facilitate consistent reproduction of desired designs, simplifying the creation process for both novice and experienced crafters.

This article will further explore the diverse types of templates available, from simple to complex, and delve into the materials and techniques employed in their application. Guidance on selecting appropriate fabrics and threads will be provided, along with detailed instructions for various stitching patterns.

Tips for Utilizing Bear-Shaped Toy Quilting Templates

Successful execution of quilted toy projects relies on careful consideration of several factors, from material selection to stitching techniques.

Tip 1: Fabric Selection: Opt for tightly woven fabrics like cotton or linen for optimal quilting results. Loosely woven fabrics can stretch and distort during the quilting process, compromising the finished product’s appearance.

Tip 2: Template Preparation: Ensure accurate template transfer onto the fabric. Clear tracing lines facilitate precise cutting and stitching, leading to a more professional outcome.

Tip 3: Batting Choice: Consider the desired thickness and loft of the finished toy when selecting batting. Thinner batting offers greater flexibility for intricate designs, while thicker batting provides more plushness.

Tip 4: Stitching Techniques: Employ consistent stitching lengths and tensions for a uniform quilted appearance. Varying stitch lengths can create an uneven, unprofessional finish.

Tip 5: Seam Allowances: Adhere to the specified seam allowances in the chosen template. Inconsistent seam allowances can result in ill-fitting pieces and a distorted final shape.

Tip 6: Thread Selection: Choose a thread appropriate for the chosen fabric and batting. A strong, high-quality thread will ensure the durability of the finished product.

Tip 7: Needle Selection: Utilize a needle size appropriate for both the thread and fabric. An incorrectly sized needle can cause fabric damage or thread breakage.

Adherence to these guidelines will contribute to a well-constructed and aesthetically pleasing finished product, showcasing the craftsmanship involved in quilted toy creation.

These tips provide a foundation for successful project execution. The following section will delve into advanced techniques and design considerations.

1. Template Design

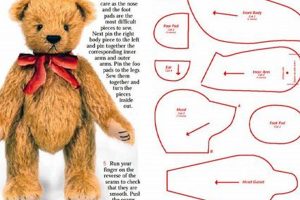

Template design forms the foundation of a quilted teddy bear pattern, dictating the final product’s appearance and construction. A well-crafted template ensures accurate piece placement and facilitates the creation of complex quilted designs. Understanding the nuances of template design is essential for achieving desired aesthetic and structural outcomes.

- Shape and Proportion:

Templates define the overall shape and proportions of the bear, from the curvature of its head to the length of its limbs. Variations in template shape can produce drastically different bear styles, ranging from traditional to more contemporary interpretations. Accurate proportions are crucial for a balanced and aesthetically pleasing final product. For instance, a template with elongated limbs will result in a longer, leaner bear compared to one with shorter, stubbier limbs.

- Seam Allowances:

Templates incorporate seam allowances, the designated space between the stitching line and the raw edge of the fabric. Consistent and accurate seam allowances are critical for proper piece alignment and a well-constructed finished product. Insufficient seam allowances can lead to difficulty in joining pieces, while excessive allowances can result in a smaller finished size than intended. Standard seam allowances for quilted toys typically range from inch to inch.

- Quilting Lines:

Template design often includes markings for quilting lines, guiding the placement of stitches that create the quilted effect. These lines can be simple geometric shapes, such as diamonds or squares, or more complex, curved designs. The placement and density of quilting lines influence the final texture and visual appeal of the bear. Dense quilting lines create a more rigid and textured surface, while sparsely placed lines offer greater flexibility and a softer feel.

- Marking Key Features:

Templates may also include markings for key features such as eye placement, ear position, and mouth embroidery. These markings ensure consistent placement of these features, contributing to the overall symmetry and aesthetic balance of the finished bear. Accurate placement of these features is essential for creating a realistic and expressive final product.

These facets of template design contribute significantly to the successful execution of a quilted teddy bear pattern. Careful consideration of each element, from the initial shaping to the placement of quilting lines, ensures a well-crafted and aesthetically pleasing final product. The choice of template ultimately dictates the character and style of the finished bear, highlighting the importance of template design in the crafting process.

2. Fabric Choice

Fabric choice significantly influences the aesthetic, tactile quality, and durability of a quilted teddy bear. Material selection impacts the effectiveness of the quilting pattern, the overall appearance of the finished product, and its longevity. Understanding the interplay between fabric properties and quilting techniques is crucial for achieving desired results.

Fabric weight and weave directly affect the visibility and definition of the quilted pattern. Lightweight, loosely woven fabrics, such as cotton batiste, may not hold the quilting stitches effectively, resulting in a less defined pattern. Conversely, denser, tightly woven fabrics, like quilting cotton or linen, provide a stable base for stitching, showcasing the quilted design more prominently. For example, a complex quilting pattern on a lightweight fabric might appear muddled, while the same pattern on a denser fabric would be crisp and well-defined. Furthermore, fabric texture contributes to the tactile experience of the finished bear. Soft, plush fabrics like minky or fleece create a cuddly feel, while smoother fabrics like cotton or linen offer a different tactile sensation. The choice depends on the desired outcome.

Durability is another key consideration. Choosing robust fabrics, such as denim or canvas, contributes to a longer-lasting toy, especially for children. Delicate fabrics like silk or satin, while aesthetically pleasing, are less suited for toys subjected to regular handling. Appropriate fabric selection ensures that the quilted teddy bear withstands wear and tear, preserving its appearance and structure over time. The interplay between fabric choice and quilting pattern is a fundamental element in crafting a successful and enduring quilted teddy bear. Selecting materials based on their properties and intended usage ensures a harmonious balance of aesthetics, texture, and longevity.

3. Stitching Technique

Stitching technique is integral to the final appearance and structural integrity of a quilted teddy bear. The choice of stitch type, stitch length, and thread tension significantly influences the definition of the quilting pattern, the durability of the seams, and the overall aesthetic of the finished product. Different stitching techniques offer varied levels of visual and structural impact. For example, a running stitch, characterized by its simple, straight line, creates a subtle quilted effect, while a more complex stitch, like a feather stitch, adds a decorative element and enhances visual interest. Stitch length also plays a crucial role; shorter stitch lengths provide greater control and finer detail, while longer stitches create a looser, more relaxed appearance. The interplay between stitch type and length allows for a range of textural and visual effects, contributing to the unique character of each quilted bear.

The structural integrity of the seams relies heavily on appropriate stitching techniques. A backstitch, known for its strength and durability, is ideal for securing seams and preventing unraveling. This is particularly important in areas subjected to stress, such as the attachment points for limbs. Conversely, a slip stitch, often used for invisible closures, provides a discreet finish but may not offer the same level of strength. Selecting the appropriate stitching technique for different sections of the bear ensures both aesthetic appeal and structural soundness. Using a backstitch for joining body panels while employing a slip stitch for closing openings demonstrates a strategic approach to construction. This understanding of various stitching techniques allows crafters to tailor their approach, achieving both desired aesthetic and functional outcomes.

Mastering stitching techniques is fundamental to achieving a well-crafted and durable quilted teddy bear. The choice of stitch type, length, and tension directly impacts the final product’s visual appeal and structural integrity. Utilizing appropriate techniques for different construction stages is paramount. The selection and application of stitching techniques serve as a testament to the crafters skill and directly influence the quality and longevity of the finished piece.

4. Batting Selection

Batting selection significantly influences the loft, warmth, and overall aesthetic of a quilted teddy bear. Different batting materials exhibit unique properties that affect the finished product’s feel, drape, and durability. Understanding these properties is crucial for selecting the appropriate batting to achieve desired outcomes. The choice of batting interacts directly with the quilted pattern, impacting its visual prominence and textural definition. For instance, a low-loft batting, such as cotton or bamboo, allows for intricate quilting details to be showcased without excessive bulk, resulting in a crisper, more defined pattern. Conversely, a high-loft batting, like polyester or wool, creates a plusher, more rounded appearance, potentially obscuring finer quilting details but providing added warmth and softness. The interplay between batting choice and quilting pattern necessitates careful consideration to achieve the desired balance of texture and visual definition.

The desired tactile quality of the finished bear also dictates batting selection. Natural fibers, such as cotton or wool, offer breathability and a softer touch, while synthetic fibers, like polyester, provide resilience and resistance to allergens. Wool batting, known for its warmth and loft, creates a cuddly and insulating layer, making it ideal for heirloom-quality bears. Conversely, a low-loft cotton batting provides a lighter, less bulky feel, suitable for bears intended for warmer climates or for decorative purposes. Practical considerations, such as washability and drying time, also influence material selection. Synthetic battings often offer easier care compared to natural fibers, requiring less specialized cleaning methods and drying more quickly. This practicality is particularly important for toys intended for frequent handling or use by young children. Choosing the appropriate batting based on desired tactile qualities and care requirements ensures a finished product suited to its intended purpose.

Appropriate batting selection ensures a harmonious balance of aesthetics, function, and practicality. Understanding the interplay between batting properties, quilting patterns, and intended use is crucial for crafting a successful quilted teddy bear. Careful consideration of these factors results in a finished product that meets expectations in terms of appearance, feel, and longevity. The choice of batting contributes significantly to the overall quality and character of the finished piece, influencing its tactile appeal and overall aesthetic.

5. Assembly Process

The assembly process directly impacts the final form and structural integrity of a quilted teddy bear derived from a pattern. A precise assembly process, adhering to the pattern’s instructions, ensures correct alignment of quilted components, resulting in a symmetrical and well-proportioned final product. Deviation from the prescribed assembly sequence can lead to misaligned seams, distorted shapes, and compromised structural integrity. For instance, attaching limbs before joining the front and back body panels can result in awkward positioning and difficulty in achieving proper closure. The pattern serves as a roadmap, guiding the assembly process and ensuring that individual quilted components are integrated correctly to achieve the intended three-dimensional form.

The complexity of the assembly process correlates with the intricacy of the quilted teddy bear pattern. Simple patterns, featuring basic shapes and minimal quilting, often involve a straightforward assembly process with fewer components and seams. Conversely, complex patterns, incorporating intricate quilting designs and multiple body segments, necessitate a more involved assembly process with precise alignment and joining of numerous components. Consider a pattern featuring a patchwork design on the bear’s body. The patchwork sections must be assembled accurately before joining the front and back body panels, requiring careful attention to seam alignment and pattern matching. Understanding the pattern’s complexity informs the assembly approach, enabling crafters to anticipate challenges and allocate sufficient time and resources. This understanding also emphasizes the pattern’s role as a blueprint, outlining not just the visual design but also the construction process itself.

A meticulous assembly process ensures the successful realization of the quilted teddy bear pattern. Precise alignment, adherence to the patterns instructions, and an understanding of the pattern’s complexity contribute to a well-constructed, aesthetically pleasing finished product. The assembly process represents the culmination of design and execution, transforming a two-dimensional pattern into a three-dimensional object. Mastery of this process is crucial for achieving the intended design and ensuring the structural integrity and aesthetic appeal of the finished quilted teddy bear.

6. Finishing Details

Finishing details represent the final stage in bringing a quilted teddy bear pattern to life, elevating the project from a sewn object to a character-rich creation. These details, while seemingly small, profoundly impact the overall aesthetic and perceived quality of the finished bear. Consider the placement of eyes. Simple button eyes create a classic, childlike appeal, while intricately embroidered eyes convey a more sophisticated, heirloom quality. Similarly, the addition of embroidered facial features, such as a nose and mouth, imbues the bear with personality and expression. The type of thread used for these details further enhances their impact. A high-sheen embroidery thread adds a touch of sparkle and highlights facial features, while a matte thread offers a more subdued, understated effect. The strategic use of finishing details transforms the bear from a simple toy into a unique, expressive creation.

The choice of finishing details should complement the quilted teddy bear pattern and the chosen fabrics. A rustic, patchwork bear might benefit from simple wooden button eyes and embroidered features using a natural-fiber thread. Conversely, a bear crafted from luxurious velvet might be enhanced with glass eyes and intricate embroidery using a silk thread. This harmonious integration of finishing details with the overall design creates a cohesive and aesthetically pleasing result. For instance, a bear featuring a complex quilted floral pattern might be complemented by embroidered flower details on its paws, further enhancing the thematic unity. The careful consideration of these details demonstrates an attention to craftsmanship and elevates the perceived value of the finished piece.

Finishing details, while often overlooked, are essential for completing the narrative of a quilted teddy bear pattern. These details add personality, enhance the aesthetic appeal, and contribute to the overall perceived quality of the finished product. Successful integration of finishing details requires careful consideration of the chosen pattern, fabrics, and desired aesthetic outcome. The thoughtful application of these final touches transforms a sewn object into a cherished keepsake, imbued with character and charm. The significance of finishing details lies not merely in their visual impact but in their ability to complete the creative vision, imbuing the finished bear with a unique personality and enduring appeal.

Frequently Asked Questions

This section addresses common inquiries regarding quilted teddy bear patterns, offering clarity on various aspects of design, material selection, and construction techniques.

Question 1: What fabric types are most suitable for quilted teddy bear patterns?

Tightly woven fabrics like quilting cotton, linen, or corduroy are recommended for optimal quilting results. These fabrics hold their shape well during the quilting process and provide a stable base for stitching. Loosely woven fabrics may stretch or distort, compromising the finished product’s appearance.

Question 2: What type of batting is best for achieving a cuddly, plush feel?

Polyester batting or wool batting provides excellent loft and softness, creating a cuddly feel. Polyester offers hypoallergenic properties and easy care, while wool provides natural warmth and breathability.

Question 3: How can seam allowance variations be avoided when working with a quilted teddy bear pattern?

Accurate template tracing and precise cutting techniques are crucial for maintaining consistent seam allowances. Using a rotary cutter and ruler ensures clean, straight cuts, while careful pinning and stitching maintain accuracy during assembly.

Question 4: What stitching techniques are recommended for securing seams and creating a durable finished product?

A backstitch offers superior strength and durability for securing seams, particularly in high-stress areas. A slip stitch provides a discreet finish for closing openings, while a running stitch can be used for decorative quilting lines.

Question 5: How can one adapt a quilted teddy bear pattern to create different sizes?

Enlarging or reducing the pattern pieces using a photocopier or digital software allows for size adjustments. Maintaining consistent seam allowances is crucial when resizing to ensure proper proportions and assembly.

Question 6: What finishing details can enhance the character and personality of a quilted teddy bear?

Embroidered facial features, such as eyes, noses, and mouths, add personality. Button eyes offer a classic look, while decorative elements like ribbons, bows, or clothing items further enhance the bear’s character.

Understanding these frequently asked questions provides a solid foundation for successfully navigating the creation of a quilted teddy bear from a pattern. Careful consideration of materials, techniques, and finishing details ensures a well-crafted and cherished final product.

The subsequent section delves into advanced techniques for customizing and embellishing quilted teddy bears, expanding creative possibilities.

Conclusion

Exploration of quilted teddy bear patterns reveals their multifaceted nature, encompassing design considerations, material selection, construction techniques, and finishing details. Successful execution hinges on a thorough understanding of these elements. Template design dictates the overall form and quilting lines, influencing both aesthetic and structural integrity. Fabric choice impacts the visibility of the quilting pattern and the tactile quality of the finished product. Stitching techniques affect seam durability and decorative elements. Batting selection determines loft, warmth, and overall feel. Meticulous assembly ensures proper form and structural soundness. Judicious application of finishing details adds personality and elevates perceived quality. Each element contributes significantly to the final outcome, transforming a two-dimensional pattern into a three-dimensional, character-rich creation.

The enduring appeal of quilted teddy bear patterns lies in their capacity to blend artistry and craftsmanship. These patterns offer a framework for creative expression, enabling crafters to transform simple materials into cherished objects imbued with individual style and enduring charm. Further exploration of advanced techniques and design variations offers continued opportunities for innovation and personalization within this timeless craft.