A plan or blueprint for constructing a stuffed toy bear, typically made of fabric, provides detailed instructions, shapes, and measurements for cutting and assembling the various components. These plans can range from simple designs suitable for beginners to intricate patterns for experienced crafters, often incorporating specialized techniques for shaping features like the head, limbs, and body. Examples include patterns for traditional jointed bears, miniature bears, or character-themed bears.

Such plans are indispensable for replicating specific designs and ensuring consistent results. They offer a structured approach to the creation process, simplifying complex tasks and minimizing potential errors. Historically, these resources have played a crucial role in preserving and disseminating toy-making traditions, enabling the creation of cherished keepsakes across generations. These plans empower both hobbyists and professionals to produce high-quality stuffed toys with precision and detail.

This article will explore various aspects of creating stuffed toys from these resources, including fabric selection, sewing techniques, stuffing materials, and finishing touches. Further discussion will delve into the diverse range of available designs, from classic to contemporary, and offer guidance for selecting the appropriate plan for different skill levels.

Tips for Using Stuffed Toy Bear Construction Plans

Careful consideration of several factors contributes significantly to the successful execution of a stuffed toy bear project. These tips offer guidance for achieving optimal results and a satisfying crafting experience.

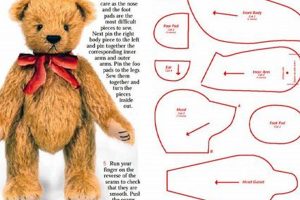

Tip 1: Fabric Selection: Opt for high-quality, durable fabrics suitable for frequent handling. Closely woven materials like mohair, plush, or fleece prevent stuffing from showing through. Consider the desired texture and appearance when selecting materials.

Tip 2: Precise Cutting: Accurate cutting is essential for proper assembly. Utilize sharp scissors and follow pattern markings meticulously to ensure symmetry and correct component sizes.

Tip 3: Seam Allowances: Adhere to specified seam allowances consistently. Inconsistent seam allowances can result in ill-fitting pieces and a distorted final product.

Tip 4: Turning and Stuffing: Employ appropriate tools, such as turning sticks or hemostats, to turn narrow limbs and appendages right-side out. Distribute stuffing evenly for a uniform and aesthetically pleasing shape. Consider using different stuffing materials for varying firmness levels.

Tip 5: Secure Closures: Employ strong, invisible stitches for closing seams and attaching limbs. Reinforce joints for added durability, particularly for toys intended for children.

Tip 6: Embellishment Choices: Select embellishments such as eyes, noses, and mouths that complement the design and enhance the bear’s character. Securely attach these elements to prevent detachment.

Tip 7: Pattern Adjustments: Understand how to adjust patterns for size modifications. Scaling requires careful recalculation of all measurements to maintain proportions.

Adherence to these guidelines will significantly enhance the quality and longevity of the finished product, resulting in a well-crafted, cherished keepsake.

By understanding the nuances of material selection, construction techniques, and finishing details, one can elevate a simple project into a work of art. The following section will provide further insights into advanced techniques and customization options.

1. Design Choice

Design choice represents a pivotal decision within the process of utilizing a plan for constructing a stuffed toy bear. This choice influences numerous factors, from the bear’s overall aesthetic to the required construction techniques. A pattern intended for a realistic bear necessitates specific shaping and jointing techniques, influencing fabric choices like mohair or alpaca for a lifelike texture. Conversely, a pattern designed for a stylized bear might prioritize simplified shapes and vibrant, patterned fabrics. The design choice establishes the foundational framework for subsequent decisions throughout the project. A whimsical bear design may incorporate exaggerated features or unusual proportions, while a traditional design adheres to classic teddy bear aesthetics. This initial choice significantly impacts the selection of materials, embellishments, and construction methods.

Consider a pattern designed for a miniature bear. Such a design necessitates precise stitching and careful attention to small details, potentially requiring specialized tools. Alternatively, a pattern for a large, jointed bear might emphasize robust construction techniques and durable materials to withstand wear and tear. The design choice effectively dictates the project’s trajectory, influencing the maker’s approach to every stage of the process, from material acquisition to final assembly.

Successful project outcomes depend heavily on a well-considered design choice that aligns with the creator’s skill level and desired aesthetic. An informed selection establishes a solid foundation for a satisfying crafting experience. Awareness of design nuances empowers makers to navigate the complexities of pattern interpretation and material selection, ultimately leading to a finished product that reflects the intended vision. Consideration should be given to the complexity of the pattern, the availability of appropriate materials, and the desired outcome before commencing the project.

2. Fabric Selection

Fabric selection holds a crucial position in the realization of a stuffed toy bear construction plan. The chosen material directly impacts the final product’s appearance, durability, and tactile qualities. Pattern specifications often recommend suitable fabric types to achieve the intended design aesthetic. For instance, a pattern designed for a vintage-style bear might suggest mohair or alpaca for a traditional, luxurious feel. Conversely, a pattern for a whimsical, contemporary bear might recommend brightly colored fleece or plush fabrics. Fabric weight and texture also play critical roles. Lightweight fabrics drape differently than heavier fabrics, impacting the bear’s overall shape and the way the pattern translates into three dimensions. A dense, short-pile plush creates a smooth, uniform surface, while a longer pile fabric adds texture and visual interest. The interplay between fabric characteristics and pattern design necessitates careful consideration during material selection.

Practical implications of fabric selection extend beyond aesthetics. Durability considerations are paramount, especially for toys intended for children. Tightly woven fabrics resist wear and tear, while loosely woven fabrics may be prone to fraying or tearing. The fabric’s cleanability also factors into its suitability. Machine-washable fabrics offer practicality for toys subjected to frequent handling. Furthermore, fabric selection influences the construction process itself. Some fabrics are easier to cut and sew than others. Stretchy fabrics, for instance, may require specialized needles and techniques to prevent puckering or distortion. Aligning fabric characteristics with pattern requirements ensures a smoother construction process and a more successful outcome. Choosing an appropriate material significantly impacts the ease of manipulation, stitching, and turning during assembly.

Effective material selection stems from understanding the interplay between fabric properties and design objectives. Disregard for compatibility can lead to challenges during construction and a final product that deviates from the intended design. A mismatch between pattern complexity and fabric choice can result in construction difficulties, potentially impacting the structural integrity and overall appearance of the finished bear. Therefore, careful evaluation of fabric characteristics, including drape, texture, durability, and ease of manipulation, ensures the chosen material complements the pattern requirements, ultimately leading to a well-crafted and aesthetically pleasing finished product. This understanding enhances the likelihood of achieving a successful outcome, transforming a two-dimensional pattern into a three-dimensional realization that embodies the intended design vision.

3. Seam Allowance

Seam allowance, the fabric width between the raw edge and the stitching line, represents a critical element within a teddy bear sewing pattern. Its precise measurement and consistent application significantly influence the final dimensions and structural integrity of the finished bear. Understanding its role is crucial for successful project execution.

- Dimensional Accuracy

Seam allowance directly impacts the finished size of the bear. A pattern designed with a -inch seam allowance will result in a slightly larger bear than the same pattern constructed with a -inch seam allowance. Inconsistent seam allowances across different pattern pieces can lead to mismatched components and assembly difficulties. Accurate adherence to the specified seam allowance ensures proper fit and proportions.

- Structural Integrity

Adequate seam allowance provides sufficient material for a secure seam, contributing to the overall durability of the bear. Narrow seam allowances increase the risk of seam ripping, especially under stress. Wider seam allowances, while offering more security, can also create bulk, particularly in smaller areas like curved seams or tight corners. The chosen seam allowance should balance strength with aesthetic considerations.

- Pattern Adjustments

Altering seam allowance requires careful consideration. Reducing the seam allowance can increase the finished size, while increasing it can decrease the size. Such adjustments necessitate recalculating pattern piece dimensions to maintain proper proportions. Understanding the relationship between seam allowance and pattern dimensions is crucial for successful modifications.

- Finishing Techniques

Seam allowance interacts with various finishing techniques. Techniques like clipping curves or notching corners prevent bulk and ensure smooth, flat seams. The chosen seam allowance influences the effectiveness of these techniques. For instance, a narrow seam allowance may restrict the ability to clip curves effectively, while a wider allowance provides more material for manipulation.

The interplay between seam allowance, pattern design, and construction techniques underscores its significance in achieving a well-crafted teddy bear. Precise adherence to specified seam allowances ensures proper component fit, structural integrity, and the realization of the intended design. Disregarding seam allowance guidelines can compromise the project’s success, leading to dimensional inaccuracies, structural weaknesses, and an overall unsatisfactory outcome. Mastery of seam allowance principles contributes to the creation of a polished and professional-looking finished product.

4. Pattern Layout

Pattern layout plays a crucial role in the efficient and successful execution of a teddy bear sewing pattern. It refers to the strategic arrangement of pattern pieces on fabric before cutting. Effective pattern layout optimizes material usage, minimizes waste, and ensures the correct grain alignment for each component. Grain direction, the orientation of fabric threads, influences the final appearance and drape of the finished bear. Proper alignment prevents stretching or distortion in critical areas like the head and limbs. A well-considered layout accommodates all pattern pieces within the available fabric, maximizing material utilization and minimizing remnants. For example, aligning directional nap fabrics, like velvet or plush, in a consistent direction across all pattern pieces ensures a uniform appearance. Conversely, improper nap alignment can result in noticeable variations in color and texture, detracting from the finished product’s aesthetics. Complex patterns, with numerous small pieces, benefit from careful planning to avoid wasteful offcuts. Prioritizing larger pieces and nesting smaller pieces within available spaces reduces fabric consumption. This efficiency becomes particularly important when working with expensive or limited-quantity materials.

Several factors influence pattern layout decisions. Fabric width and length restrict placement options. Pattern piece size and shape dictate how they fit together. Fabric characteristics, like stretch or directional prints, also influence layout strategy. For instance, a pattern layout for a stretchy fabric requires careful consideration of grain direction to prevent unwanted distortion during construction. Similarly, when working with patterned fabrics, the layout must account for pattern matching across seams to maintain design continuity. Failing to consider these factors can result in insufficient fabric, misaligned pattern pieces, and a compromised final product. Software tools and online resources can assist with layout optimization, particularly for complex projects. These tools allow users to input fabric dimensions and pattern piece specifications to generate efficient layout options, minimizing waste and maximizing material utilization.

Successful execution of a teddy bear sewing pattern hinges on a comprehensive understanding of pattern layout principles. Efficient material utilization, correct grain alignment, and consideration of fabric characteristics contribute significantly to the quality and structural integrity of the finished bear. Conversely, neglecting these aspects can lead to material shortages, construction challenges, and a compromised aesthetic outcome. Mastery of pattern layout techniques empowers crafters to translate two-dimensional patterns into three-dimensional creations effectively, optimizing material usage and ensuring a polished, professional result. This understanding transforms the seemingly mundane task of arranging pattern pieces into a strategic element that contributes significantly to the overall success of the project.

5. Cutting Accuracy

Cutting accuracy represents a fundamental aspect of successfully executing a teddy bear sewing pattern. Precise cutting directly influences the proper fit and assembly of the bear’s components, ultimately impacting the final product’s structural integrity and aesthetic appeal. Deviations from prescribed cutting lines can lead to misaligned seams, distorted shapes, and a compromised overall appearance.

- Component Alignment

Accurate cutting ensures that each pattern piece conforms to the intended design specifications. Precise adherence to cutting lines ensures proper alignment of seams during assembly. For instance, accurately cut notches and markings facilitate precise joining of the bear’s head to its body, ensuring a seamless and symmetrical connection. Deviation from these lines can result in mismatched components, leading to a distorted final product.

- Shape Integrity

The shape of each pattern piece dictates the final form of the bear. Accurate cutting preserves the intended curves, angles, and proportions of each component. For example, accurately cutting the curved edges of the bear’s ears ensures they maintain their proper shape after turning and stuffing. Inaccurate cutting can result in distorted ears that detract from the bear’s overall appearance. Precise execution along designated cut lines ensures the finished bear replicates the pattern’s intended form.

- Seam Matching

Accurate cutting facilitates proper seam alignment during assembly. Precisely cut edges ensure that seams match seamlessly, creating clean, professional-looking joins. For example, accurate cutting of the bear’s leg seams ensures that the front and back leg pieces align correctly, creating a smooth, even seam. Inaccurate cutting can lead to jagged seams, uneven joins, and a compromised final product.

- Fabric Grain Alignment

Maintaining the fabric’s grain, the direction of the fabric threads, contributes to the structural integrity and drape of the finished bear. Cutting pattern pieces accurately along the specified grainlines ensures that the fabric behaves as intended, preventing stretching or distortion in critical areas. For instance, cutting the bear’s body pieces on the lengthwise grain ensures that the fabric hangs correctly, maintaining the bear’s intended shape. Inaccurate grain alignment can lead to warped or misshapen components, compromising the bear’s overall appearance and structural integrity.

Cutting accuracy, therefore, underpins the entire construction process of a teddy bear. Precise cutting, guided by a well-drafted pattern, ensures that individual components fit together seamlessly, resulting in a finished product that reflects the intended design and exhibits structural integrity. Conversely, inaccurate cutting can compromise the project’s success, leading to a range of issues from misaligned seams and distorted shapes to a weakened overall structure. Mastery of cutting techniques directly translates into a higher quality finished product, underscoring the importance of precision in every cut.

6. Assembly Instructions

Assembly instructions constitute the roadmap within a teddy bear sewing pattern, guiding the sequential construction of the bear from individual fabric components. Clear, comprehensive instructions are essential for a successful outcome, translating the two-dimensional pattern into a three-dimensional object. These instructions bridge the gap between design concept and physical realization, providing the necessary steps for transforming raw materials into a finished teddy bear.

- Component Joining Order

Instructions dictate the precise order in which individual pattern pieces are joined. This sequence ensures proper construction and prevents assembly errors. For example, instructions might specify joining the bear’s head components before attaching the head to the body. Deviating from this order could complicate subsequent steps or even render certain assembly actions impossible. Proper sequencing ensures a logical and efficient construction process.

- Seam Type and Placement

Instructions specify the type of seam required for each connection, such as a straight seam, a curved seam, or a French seam. They also indicate precise seam placement, ensuring structural integrity and aesthetic appeal. For instance, instructions might specify a ladder stitch for closing the opening used for turning and stuffing the bear. Using an incorrect seam type or misplacing a seam can compromise the bear’s strength and appearance.

- Turning and Stuffing Techniques

Instructions provide guidance on turning assembled components right-side out and stuffing them to achieve the desired shape and firmness. They may recommend specific tools or techniques for navigating tight corners or intricate shapes. For example, instructions might suggest using a turning tool to turn narrow limbs right-side out without damaging the fabric. Proper turning and stuffing techniques contribute significantly to the bear’s final form and tactile qualities.

- Finishing Details and Embellishments

Instructions detail the final steps, including attaching facial features, such as eyes, nose, and mouth, and adding embellishments like ribbons or bows. These details contribute significantly to the bear’s character and personality. Clear instructions ensure these elements are placed correctly and securely attached. For instance, instructions might specify using safety eyes for a child’s toy, ensuring adherence to safety standards. Careful attention to finishing details elevates the finished product from a simple sewn object to a cherished keepsake.

The clarity and precision of assembly instructions directly correlate with the success of a teddy bear sewing project. Well-crafted instructions guide the maker through each stage of the construction process, ensuring proper component assembly, structural integrity, and aesthetic appeal. Conversely, ambiguous or incomplete instructions can lead to confusion, errors, and a less-than-satisfactory final product. Therefore, carefully following each step within the assembly instructions ensures the successful transformation of a two-dimensional pattern into a three-dimensional, cherished companion.

7. Finishing Techniques

Finishing techniques represent the crucial final stage in bringing a teddy bear sewing pattern to life, transforming a sewn object into a character-rich creation. These techniques encompass a range of processes directly impacting the bear’s appearance, durability, and overall aesthetic. The chosen finishing techniques are intrinsically linked to the specific teddy bear sewing pattern, with design choices influencing technique selection.

Consider jointing methods. Traditional teddy bears often employ cotter pin or disc jointing, allowing for articulated limbs and head movement. These techniques require specific considerations during the pattern design and construction phases, impacting seam allowances and component assembly. Secure jointing ensures durability and longevity, crucial for playability. Alternatively, a pattern for a non-jointed, sculpted bear necessitates different finishing approaches. Emphasis shifts towards shaping and sculpting techniques applied during stuffing and closing, influencing material choices and stitching methods. The pattern itself may incorporate specific markings or instructions to guide the sculpting process. For example, strategically placed darts or gathers can create subtle shaping details that enhance the bear’s character.

Facial features exemplify the transformative power of finishing techniques. Embroidered features offer a classic, handcrafted aesthetic. The pattern may include embroidery templates or detailed stitching instructions to guide precise placement and execution. Alternatively, glass or safety eyes, combined with a sculpted or applied nose, create a different look, often requiring specialized tools and attachment methods dictated by the pattern’s design. The chosen method significantly impacts the bear’s personality and perceived realism. Similarly, techniques for creating sculpted paws, using embroidery or appliqu, contribute to the bear’s overall character. The pattern’s instructions guide these processes, influencing material choices and stitching techniques. Careful execution of these finishing touches elevates the bear from a simple sewn object to a detailed, character-rich creation. Understanding the interplay between pattern design and finishing techniques is essential for achieving a successful and aesthetically pleasing outcome.

Frequently Asked Questions

This section addresses common inquiries regarding the utilization of blueprints for constructing stuffed toy bears.

Question 1: What differentiates a beginner’s plan from an advanced one?

Beginner plans typically feature simpler shapes, fewer pattern pieces, and basic construction techniques. Advanced plans may involve complex curves, intricate jointing methods, and specialized sewing skills.

Question 2: What fabric types are most suitable for these projects?

Suitable fabrics include mohair, alpaca, plush, and fleece. Fabric selection depends on the desired texture, durability, and aesthetic of the finished bear. Consider factors like pile length, weave density, and ease of cleaning.

Question 3: How does one adjust a plan for a different size?

Resizing requires scaling all pattern pieces proportionally. Specialized software or manual recalculations, maintaining original proportions, are necessary to avoid distortions.

Question 4: What are the essential tools required for these projects?

Essential tools include sharp scissors, sewing needles, strong thread, pins, a seam ripper, stuffing material, and potentially specialized tools like a turning stick or hemostat for intricate areas.

Question 5: How can seam ripping be minimized during the construction process?

Careful pinning, accurate cutting, and adherence to seam allowances minimize seam ripping. Using appropriate thread weight and needle size for the chosen fabric also contribute to seam integrity.

Question 6: What resources are available for individuals new to this craft?

Numerous online tutorials, workshops, and instructional books offer guidance for beginners. Starting with a simple pattern and gradually increasing complexity allows skill development.

Careful consideration of these frequently asked questions empowers individuals to approach projects with confidence and achieve satisfactory results. Selecting an appropriate pattern, understanding material characteristics, and employing proper techniques contribute significantly to the successful creation of a cherished keepsake.

The following section will explore advanced techniques for enhancing the realism and character of stuffed toy bears.

Conclusion

Teddy bear sewing patterns provide the foundational blueprint for crafting these cherished companions. Exploration of design choices, fabric selection, seam allowance considerations, pattern layout strategies, cutting accuracy, assembly instructions, and finishing techniques reveals the multifaceted nature of this craft. Each element contributes significantly to the successful realization of a finished bear, impacting its appearance, durability, and character. From the initial design concept to the final finishing touches, adherence to pattern guidelines and careful execution of each step ensures a well-crafted, enduring keepsake.

The enduring appeal of handcrafted teddy bears lies in their ability to embody both artistry and sentiment. A well-chosen and meticulously executed teddy bear sewing pattern facilitates the creation of a unique, personalized object imbued with emotional significance. Continued exploration of advanced techniques and design variations promises further evolution within this timeless craft, ensuring the enduring legacy of these treasured companions for generations to come. The potential for creativity within this craft remains boundless, offering endless opportunities for personal expression and the creation of cherished heirlooms.