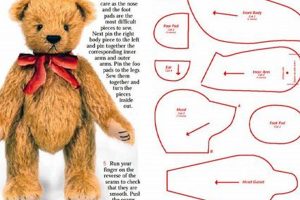

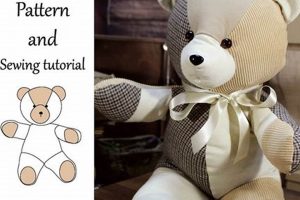

A template, typically printed on paper or available digitally, provides instructions and outlines for crafting a stuffed toy bear. These templates usually include cutting layouts for fabric pieces, markings for seam allowances, and detailed steps for assembly. An example might include separate pattern pieces for the head, body, limbs, and ears, along with recommendations for suitable fabrics.

Such templates simplify the process of creating stuffed bears, allowing both novice and experienced crafters to achieve professional-looking results. They offer a standardized approach, ensuring consistency in size and shape, while still permitting customization through fabric choice and embellishments. Historically, these templates played a significant role in the popularization of homemade toys, providing accessible instructions for replicating popular designs. This accessibility democratized toy making, allowing individuals to create personalized gifts and keepsakes.

Understanding the components and utilization of these resources is fundamental to successful toy creation. This article will further explore topics such as fabric selection, sewing techniques, stuffing materials, and finishing details relevant to this craft.

Tips for Utilizing Teddy Bear Sewing Patterns

Careful consideration of several factors contributes significantly to successful project outcomes when crafting stuffed bears. These tips offer guidance for optimal results.

Tip 1: Fabric Selection: Opting for high-quality, durable fabrics like mohair, fleece, or cotton ensures longevity and a pleasing tactile experience. Closely woven fabrics prevent stuffing from showing through.

Tip 2: Accurate Cutting: Precise cutting along pattern lines is crucial for proper assembly and a polished final product. Sharp scissors and careful attention to detail are essential.

Tip 3: Marking and Notching: Transferring markings from the pattern to the fabric, including notches and darts, facilitates accurate alignment during sewing and shaping.

Tip 4: Seam Allowances: Maintaining consistent seam allowances, as specified in the pattern instructions, ensures proper fit and prevents size discrepancies.

Tip 5: Turning and Stuffing: Employing appropriate tools, such as turning sticks or hemostats, assists in cleanly turning and evenly stuffing narrow appendages. Fiberfill stuffing provides a classic plush feel.

Tip 6: Closing Seams: Utilizing an invisible ladder stitch for closing openings creates a seamless, professional finish.

Tip 7: Embellishments: Adding details like embroidered features, glass eyes, or clothing personalizes the finished bear and enhances its character.

Adhering to these guidelines ensures a streamlined construction process and contributes to a well-crafted, aesthetically pleasing finished product.

By understanding these core principles, crafters can confidently embark on projects and achieve satisfying results.

1. Template Selection

Template selection represents a foundational step in crafting a teddy bear. The chosen template dictates the final product’s size, shape, and complexity, influencing subsequent material choices and construction techniques. A well-chosen template streamlines the process and contributes significantly to a successful outcome.

- Complexity Level:

Templates range from simple designs suitable for beginners to intricate patterns demanding advanced sewing skills. Simple templates might involve basic shapes and minimal pieces, while complex versions incorporate articulated joints, detailed features, or unique construction methods. Selecting a template aligned with one’s skill level ensures a manageable and rewarding experience.

- Size and Scale:

Templates determine the finished bear’s dimensions, from miniature keepsakes to oversized companions. Consider the intended purpose and available materials when selecting a size. Smaller bears require finer fabrics and intricate stitching, while larger bears benefit from durable materials and robust construction techniques. Desired scale significantly influences material requirements and handling during assembly.

- Stylistic Variations:

Templates offer a variety of stylistic options, ranging from traditional teddy bear designs to contemporary interpretations. Classic templates feature familiar proportions and simple features, while modern templates might explore unique shapes, exaggerated features, or thematic variations. Template choice reflects desired aesthetic preferences and allows for personalized expression.

- Construction Methods:

Different templates utilize varying construction methods. Some employ traditional sewn joints, while others incorporate gussets, joints, or specialized techniques for creating specific features. Understanding the construction method outlined in a template ensures appropriate material selection and facilitates successful assembly. Template complexity directly influences the required skill set and construction timeframe.

Careful template selection establishes a project’s trajectory, influencing material choices, construction techniques, and the final product’s aesthetic. A thorough evaluation of complexity, size, style, and construction methods ensures alignment with skill level and desired outcome, ultimately contributing to a satisfying crafting experience and a well-crafted teddy bear.

2. Fabric Choice

Fabric choice represents a critical decision in teddy bear construction, directly influencing the final product’s durability, aesthetics, and tactile qualities. The chosen fabric must complement the selected pattern, considering factors like scale, complexity, and desired finish. Material properties significantly impact the bear’s longevity, washability, and overall appeal. A considered fabric choice enhances the construction process and elevates the finished product.

Material properties dictate suitability for specific patterns. Dense, tightly woven fabrics like mohair or alpaca plush lend themselves to intricate designs and detailed features, providing a luxurious texture and excellent drape. These fabrics maintain shape well and showcase intricate stitching. Conversely, looser weaves, such as fleece or cotton flannel, offer softness and affordability but might obscure fine details or require additional reinforcement in high-stress areas. Pattern complexity necessitates careful consideration of fabric weight, stretch, and texture to ensure successful construction and a pleasing final result. For instance, a delicate vintage-inspired pattern benefits from silk or rayon plush, while a robust, playful design might utilize durable corduroy or denim.

Fabric selection impacts not only aesthetics but also practicality. Washability and durability are key considerations, especially for children’s toys. Synthetic fabrics offer ease of cleaning and resistance to wear and tear, while natural fibers provide a softer touch but may require more delicate care. Ultimately, fabric choice embodies a balance between aesthetic goals, practical considerations, and compatibility with the chosen pattern. A well-informed decision elevates the finished teddy bear from a simple craft project to a cherished keepsake.

3. Cutting Accuracy

Cutting accuracy represents a pivotal element within the process of utilizing teddy bear sewing patterns. Precision during fabric cutting directly impacts the final product’s structural integrity, aesthetic appeal, and overall success of the project. Accurate cutting ensures proper alignment of pattern pieces, enabling seamless assembly and a professional finish. Conversely, inaccurate cutting introduces discrepancies in piece dimensions, leading to mismatched seams, distorted shapes, and a compromised final product. The relationship between cutting accuracy and pattern utilization is one of direct cause and effect, where precision yields positive outcomes and inaccuracies introduce challenges.

Consider a teddy bear pattern incorporating multiple curved seams, such as along the head or limbs. Precise cutting along these curves allows for smooth joining of adjacent pieces, creating a seamless, three-dimensional form. Deviations from the pattern lines during cutting, however, result in uneven edges, making proper alignment and stitching difficult. This can manifest as puckering, gaps, or strained seams, detracting from the finished bear’s appearance and potentially compromising its structural integrity. Similarly, inaccurate cutting of notched markings, essential for aligning pattern pieces, can lead to mismatched components and an overall distorted shape. These examples illustrate the practical significance of cutting accuracy in achieving a well-constructed and aesthetically pleasing teddy bear.

Achieving cutting accuracy requires careful attention to detail and the utilization of appropriate tools. Sharp fabric scissors dedicated solely to fabric cutting ensure clean, precise cuts, minimizing fraying and distortion. Rotary cutters paired with cutting mats offer an alternative for achieving straight lines and complex curves, particularly with thicker fabrics. Careful pinning of the pattern pieces to the fabric, ensuring they lie flat and wrinkle-free, further enhances precision. Ultimately, meticulous cutting practice translates directly into a higher quality finished product, reinforcing the importance of this step within the broader context of teddy bear pattern utilization. Challenges related to fabric slippage or pattern complexity can be mitigated through careful material handling and the application of appropriate cutting techniques, underscoring the importance of both skill and precision in this critical stage of the crafting process.

4. Seam Allowances

Seam allowances represent a critical technical aspect of teddy bear pattern utilization. Designated spaces between the stitching line and the raw fabric edge, seam allowances directly influence the final product’s structural integrity, dimensional accuracy, and overall finish. Understanding their function and consistent application are essential for successful teddy bear construction.

- Dimensional Accuracy:

Seam allowances contribute significantly to maintaining the intended dimensions of the finished teddy bear. Specified within the pattern, consistent seam allowances ensure that individual pattern pieces assemble correctly, resulting in a bear of the designed size and proportions. Inconsistent or inaccurately measured seam allowances can lead to size discrepancies between different body parts or an overall deviation from the intended scale. For instance, a smaller seam allowance than specified will result in a slightly larger finished piece, while a larger seam allowance results in a smaller piece.

- Structural Integrity:

Adequate seam allowances provide necessary fabric for secure seam construction, contributing to the teddy bear’s durability and longevity. Sufficient seam allowance prevents seam slippage or unraveling, particularly in high-stress areas like joints or points of articulation. Narrow seam allowances, conversely, risk compromised seam strength, potentially leading to tearing or separation during stuffing or regular handling. The width of the seam allowance should be appropriate for the fabric and anticipated stress.

- Finishing Techniques:

Seam allowances accommodate various finishing techniques, enhancing both the aesthetic and structural integrity of the finished bear. Techniques such as serging, pinking, or zigzag stitching prevent fraying and reinforce seam edges. Adequate seam allowance provides the necessary fabric width for these techniques to be applied effectively. For example, a narrow seam allowance might be insufficient for serging, limiting finishing options and potentially compromising seam durability. Seam allowance width dictates the range of applicable finishing techniques.

- Pattern Interpretation:

Accurate interpretation and consistent application of seam allowance specifications are crucial for successful pattern utilization. Patterns typically indicate the designated seam allowance width. Adhering to this specification ensures proper piece alignment and final dimensions. Deviation from the designated seam allowance, even slightly, can lead to cumulative errors affecting the overall construction and fit of the bear. Careful attention to seam allowance specifications is paramount for achieving the intended result.

Seam allowances are not merely technical details but integral components of successful teddy bear construction. Their consistent application, in accordance with pattern specifications, ensures dimensional accuracy, structural integrity, and the effective implementation of finishing techniques. Understanding the interconnectedness of seam allowances with other aspects of pattern utilization, such as fabric choice and cutting accuracy, further underscores their importance in creating a well-crafted and durable teddy bear.

5. Stuffing Technique

Stuffing technique constitutes a crucial stage in teddy bear creation, bridging the gap between a two-dimensional pattern and a three-dimensional form. Its proper execution significantly influences the final product’s aesthetic appeal, tactile qualities, and structural integrity. A thoughtfully implemented stuffing technique elevates the finished teddy bear from a simple sewn object to a cherished keepsake.

- Stuffing Material Selection:

Stuffing material choice dictates the teddy bear’s tactile qualities, weight, and overall feel. Options range from traditional polyester fiberfill, offering softness and affordability, to natural materials like wool or cotton, providing a more traditional, albeit potentially less resilient, feel. Specialty fillings, such as weighted pellets or plastic beads, offer unique tactile experiences or functional attributes. Material selection aligns with the intended use and desired aesthetic of the finished bear.

- Stuffing Density and Distribution:

Achieving appropriate stuffing density and distribution is essential for creating a well-formed, aesthetically pleasing bear. Even distribution prevents lumpiness or asymmetry, while appropriate density ensures structural integrity and a pleasing tactile experience. Overstuffing can strain seams and create a rigid, unappealing form, while understuffing results in a floppy, shapeless bear. Density considerations often vary across different body parts; the head typically requires firmer stuffing than the limbs for maintaining shape.

- Tools and Techniques:

Specific tools and techniques facilitate effective stuffing, particularly within narrow appendages or intricate shapes. Stuffing tools, such as wooden dowels or hemostats, aid in compacting and evenly distributing filling material. Specific techniques, like layering or wrapping stuffing around small components before insertion, enhance shaping and prevent clumping. These tools and techniques contribute to consistent density and prevent overfilling, ensuring structural integrity and a smooth, even finish.

- Relationship to Pattern Design:

The chosen stuffing technique must complement the teddy bear pattern. Pattern design often dictates stuffing density requirements for specific body parts, influencing material choice and distribution strategies. For instance, a pattern designed for a slim, articulated bear necessitates a different stuffing approach than a pattern for a plump, traditional teddy bear. Understanding the interplay between pattern design and stuffing technique is crucial for achieving the intended aesthetic and functional outcome.

Effective stuffing technique transforms flat pattern pieces into a three-dimensional form, imbuing the teddy bear with character and tactile appeal. Careful consideration of stuffing material, density, distribution, and the interplay between these factors and the pattern design elevates the finished product. The chosen stuffing technique ultimately contributes significantly to the teddy bear’s overall quality, longevity, and aesthetic appeal, solidifying its role as a crucial element in the crafting process.

6. Finishing Details

Finishing details represent the culmination of the teddy bear creation process, transforming a stuffed form into a character-rich, finished piece. These details, ranging from facial features to clothing and accessories, directly impact the teddy bear’s personality and perceived value. Their careful execution elevates the project from a basic craft to a personalized creation. The relationship between finishing details and the broader context of teddy bear pattern utilization is one of enhancement and individualization. While a completed, stuffed form fulfills the basic requirements of the pattern, finishing details imbue the bear with unique character and charm.

Facial features, a core component of finishing details, significantly impact the teddy bear’s expressiveness. Securely attached glass or safety eyes, combined with a thoughtfully embroidered nose and mouth, imbue the bear with personality and a sense of life. The placement and style of these features can evoke a range of emotions, from playful mischievousness to gentle serenity. Similarly, the addition of ears, carefully shaped and positioned according to the pattern, further contributes to the bear’s overall character. Consider a teddy bear intended as a gift for a child; embroidered eyelashes and a gently curved smile create a sense of warmth and comfort, enhancing its emotional value. Conversely, a bear designed as a collector’s item might feature intricately sculpted polymer clay features and hand-painted details, increasing its perceived artistic value.

Beyond facial features, additional finishing details further personalize and enhance the teddy bear. Clothing, crafted from complementary fabrics and patterns, adds another layer of character and charm. A simple ribbon tied around the neck, a miniature knitted sweater, or a fully tailored outfit transforms the bear’s appearance and expands narrative possibilities. Accessories, such as miniature spectacles, hats, or hand-sewn bags, further enhance the bear’s personality and create opportunities for storytelling. These finishing touches, while seemingly small, significantly impact the overall impression and perceived value of the finished piece. Challenges in achieving precise embroidery or securely attaching small components underscore the need for patience and precision in this final stage of the crafting process. Successfully executed finishing details solidify the transformation from sewn object to cherished keepsake, demonstrating the profound impact of these seemingly minor additions within the broader context of teddy bear creation.

Frequently Asked Questions

This section addresses common inquiries regarding teddy bear pattern utilization, offering practical guidance for various skill levels.

Question 1: What type of fabric is best suited for a beginner’s teddy bear project?

Fleece or tightly woven cotton fabrics are recommended for beginners. These materials are readily available, easy to handle, and less prone to fraying than more delicate options like mohair or alpaca plush.

Question 2: How can seam ripping be minimized during the construction process?

Careful pinning and basting before final stitching significantly reduce the need for seam ripping. Accurate cutting and consistent seam allowances also contribute to a smoother construction process.

Question 3: What techniques can be employed to ensure even stuffing distribution?

Using small amounts of stuffing at a time and employing tools like chopsticks or hemostats to reach into narrow appendages ensure even distribution and prevent lumping. Layering stuffing material can also create a smoother finish.

Question 4: What are the best methods for attaching embellishments like eyes and noses?

Safety eyes or embroidered features are recommended for teddy bears intended for young children. Strong thread and secure knots are essential for preventing detachment. For collector’s items, specialized adhesives or cotter pins may be appropriate for securing glass or polymer clay features.

Question 5: How can pattern pieces be transferred to fabric effectively?

Tracing paper and a tracing wheel offer precise transfer of pattern markings onto fabric. Alternatively, dressmaker’s carbon paper or tailor’s chalk can be used, although precision may vary depending on fabric texture and pattern complexity. Fabric weights can prevent pattern shifting during tracing.

Question 6: What are some resources for finding free or affordable teddy bear sewing patterns?

Online crafting communities, libraries, and independent pattern designers often offer free or low-cost patterns. Searching for vintage craft books or exploring online marketplaces can also yield affordable options.

Careful attention to pattern instructions, combined with these insights, contributes significantly to successful teddy bear creation. Addressing these common questions preemptively empowers crafters to navigate potential challenges and achieve desired results.

The subsequent section will delve into advanced techniques for creating articulated teddy bears.

Conclusion

Templates for constructing teddy bears provide a foundational structure for creating these cherished companions. Exploration of template selection, fabric choice, cutting accuracy, seam allowances, stuffing techniques, and finishing details reveals the interconnectedness of each step in achieving a well-crafted final product. Material selection impacts both aesthetics and durability, while precise cutting and adherence to seam allowance guidelines ensure proper construction. Stuffing technique influences the final form and tactile qualities, and finishing details imbue the bear with unique personality. Consideration of these elements, combined with meticulous execution, transforms simple materials into treasured keepsakes.

The enduring appeal of handcrafted teddy bears speaks to the power of creativity and the tangible connection between maker and creation. Templates, as guiding frameworks, empower individuals to translate imagination into physical form. Continued exploration of techniques and materials promises further evolution of this timeless craft, ensuring the enduring presence of these cherished companions for generations to come.