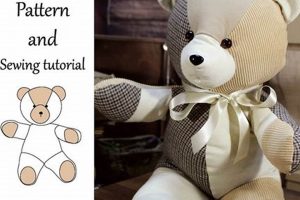

A template for crafting a stuffed toy from fabric serves as a blueprint, guiding the creation process. This template typically includes shapes to be cut from fabric, instructions for sewing these pieces together, and details for adding features like eyes, noses, and mouths. An example could be a design for a classic teddy bear with jointed limbs and a stitched-on smile.

Such templates are essential for achieving consistent results and simplifying the construction of soft toys. They allow both novice and experienced crafters to reproduce specific designs reliably. Historically, these guides were hand-drawn and shared within communities, contributing to the evolution of toymaking traditions. Today, digital formats offer widespread accessibility and precision, enabling complex designs and customizations. The availability of varied templates fosters creativity and allows for a wide array of unique creations.

The following sections will explore various aspects of soft toy design and construction, including fabric selection, sewing techniques, and embellishment options.

Tips for Utilizing Fabric Toy Templates

Successful soft toy creation relies on careful consideration of several factors. The following tips offer guidance for effectively using fabric toy templates.

Tip 1: Fabric Selection: Appropriate fabric choice impacts durability and aesthetics. Tightly woven fabrics, such as cotton twill or fleece, prevent stuffing from showing through. Consider the desired texture and appearance when selecting materials.

Tip 2: Accurate Cutting: Precise cutting ensures proper alignment and fit. Sharp scissors and careful attention to pattern lines are crucial for achieving the intended shape of each piece.

Tip 3: Seam Allowance: Adhering to the specified seam allowance is essential for proper assembly. Insufficient seam allowance can result in a smaller finished product, while excessive allowance can distort the shape.

Tip 4: Turning and Stuffing: Leaving openings for turning and stuffing requires planning. These openings should be strategically placed and large enough to allow for easy manipulation. Firm, even stuffing achieves the desired shape and feel.

Tip 5: Secure Closures: Hidden stitches or ladder stitch techniques provide secure and visually appealing closures for turning openings. Reinforced seams in high-stress areas enhance durability.

Tip 6: Embellishment Techniques: Embroidery, buttons, and safety eyes contribute to the toy’s personality. Securely attaching these elements ensures safety and longevity.

Tip 7: Pattern Adjustments: Adjusting pattern size requires an understanding of scale and proportion. Enlarging or reducing patterns should be done uniformly to maintain the intended design.

Careful attention to these details ensures successful project completion and a well-crafted finished product. These tips contribute to a satisfying crafting experience and a durable, aesthetically pleasing result.

By applying these principles, crafters can transform simple templates into cherished keepsakes.

1. Template Design

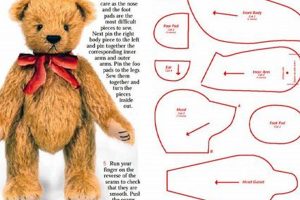

Template design serves as the foundational blueprint for a cloth teddy bear pattern. A well-crafted template dictates the final form, proportions, and construction process of the finished toy. Understanding its components is crucial for achieving the desired outcome.

- Shape and Proportion

The template outlines the individual pieces of the bear, defining its overall shape and the proportions of its head, body, limbs, and other features. A template for a classic teddy bear, for example, would feature a rounded head, a larger torso, and shorter, slightly curved limbs. These shapes, when assembled, create the recognizable teddy bear silhouette. Variations in these shapes can lead to different stylistic interpretations.

- Seams and Joints

Template design incorporates markings for seams and joints. These markings indicate where fabric pieces are to be sewn together and how the bear’s limbs will be attached. Notches and lines on the template guide placement and alignment, ensuring proper articulation and a cohesive final product. Different jointing methods, such as button joints or sewn joints, influence the bear’s poseability and durability.

- Size and Scale

Templates are designed to specific dimensions, determining the finished size of the bear. Scaling a template up or down requires careful adjustment of all components to maintain correct proportions. A miniature teddy bear pattern, for instance, would necessitate smaller, more intricate pieces than a life-sized version, impacting fabric selection and construction techniques.

- Additional Features

Templates may include markings or separate pattern pieces for additional features such as ears, a snout, or paw pads. These additions contribute to the bear’s character and realism. The complexity of these features influences the overall construction process and the skill level required to execute the design successfully.

The interplay of these facets within template design directly influences the final appearance and construction of the cloth teddy bear. A thorough understanding of these elements enables crafters to select appropriate materials, employ effective construction techniques, and achieve the desired aesthetic outcome. Ultimately, a well-designed template empowers crafters to translate a two-dimensional pattern into a three-dimensional, cherished creation.

2. Fabric Choice

Fabric selection significantly impacts the final appearance, texture, and durability of a teddy bear created from a cloth pattern. The interplay between fabric properties and pattern design influences construction techniques and the overall aesthetic. Choosing appropriate materials is crucial for achieving the desired outcome.

- Texture and Appearance

Fabric texture contributes significantly to the teddy bear’s tactile and visual appeal. Plush fabrics like minky or faux fur create a soft, cuddly feel, while tighter weaves such as cotton twill or linen offer a smoother, firmer surface. Pattern choice interacts with texture; a simple pattern benefits from a fabric with visual interest, while a complex pattern might require a more subdued texture to avoid a cluttered appearance.

- Durability and Longevity

Fabric durability dictates the toy’s resistance to wear and tear. Closely woven fabrics withstand stress better than loosely woven options. Choosing durable materials, especially for high-stress areas like seams and joints, prolongs the bear’s lifespan. Pattern design should consider fabric durability; intricate patterns might necessitate robust fabrics to prevent fraying during construction.

- Drape and Structure

Fabric drape, or how it hangs and folds, affects the final shape of the bear. A fabric with more drape results in a softer, more flowing form, while a stiffer fabric maintains a more structured silhouette. The pattern design influences fabric choice; patterns designed for a floppy, relaxed bear might benefit from a drapey fabric, whereas a pattern intended for a more upright posture requires a fabric with more structure.

- Color and Pattern

Fabric color and pattern contribute significantly to the bear’s personality and aesthetic. Solid colors offer a classic look, while printed fabrics add visual interest. The choice should complement the pattern design; a simple pattern can showcase a bold print, while a complex pattern often benefits from a simpler, more unified color scheme to avoid visual overload.

Careful consideration of these facets in fabric selection ensures the chosen material aligns with the intended design and construction process outlined in the cloth teddy bear pattern. The interplay between fabric properties and pattern design ultimately determines the successful realization of the crafted piece. Harmonizing these elements results in a well-constructed, aesthetically pleasing, and durable finished product.

3. Seam Allowance

Seam allowance, the distance between the fabric edge and the stitching line, plays a crucial role in the successful execution of a cloth teddy bear pattern. This seemingly minor detail significantly impacts the final dimensions, structural integrity, and overall appearance of the finished toy. Its careful consideration is essential throughout the construction process.

A specified seam allowance within a pattern ensures consistent sizing. Ignoring or inaccurately measuring this allowance results in deviations from the intended dimensions. For instance, a pattern designed for a 10-inch bear with a -inch seam allowance will yield a smaller finished product if a -inch seam allowance is used. Conversely, a smaller seam allowance results in a larger finished product, potentially distorting proportions and impacting the fit of adjoining pieces. Maintaining consistent seam allowance prevents such discrepancies, ensuring the final product adheres to the pattern’s design.

Beyond sizing, seam allowance contributes to the toy’s durability. Adequate seam allowance provides space for strong, secure seams, reducing the risk of tearing or fraying under stress. This is particularly important in high-stress areas such as joints and limb attachments. Insufficient seam allowance compromises structural integrity, leading to potential weaknesses in the finished toy. A wider seam allowance, within reasonable limits dictated by the pattern, often allows for stronger reinforcement and contributes to the longevity of the finished piece.

Proper seam allowance also impacts the aesthetic quality of the finished bear. Consistent seam allowances contribute to clean, professional-looking seams and smooth transitions between pattern pieces. Uneven or inadequate seam allowances can result in puckering, bunching, or visible raw edges, detracting from the overall appearance. Attention to seam allowance, therefore, contributes not only to structural integrity but also to the visual appeal of the finished product. Understanding and accurately implementing seam allowance as specified in the cloth teddy bear pattern ensures a well-constructed, durable, and aesthetically pleasing finished toy.

4. Construction Techniques

Construction techniques directly influence the final form, durability, and aesthetic qualities inherent in a cloth teddy bear derived from a pattern. The pattern serves as a guide, but the chosen construction techniques dictate how the two-dimensional design translates into a three-dimensional object. Specific techniques impact the structural integrity, poseability, and overall appearance of the finished bear. For example, the method used to create and attach limbs significantly affects the bear’s range of motion. Button joints offer greater flexibility, while securely sewn joints prioritize stability. Similarly, the choice between a ladder stitch or a more visible whip stitch for closing seams impacts both the toy’s durability and its aesthetic appeal. An understanding of various construction techniques empowers crafters to select methods best suited to their skill level and the desired outcome.

Different construction techniques offer varying levels of complexity and control. Hand-sewing techniques, while time-consuming, offer precision and control over stitch placement, crucial for intricate details and delicate fabrics. Machine sewing offers speed and efficiency, ideal for larger projects or sturdier fabrics. The choice of stuffing material also plays a significant role. Fiberfill stuffing creates a soft, pliable form, while denser materials offer greater firmness and shape retention. The chosen construction techniques influence the interaction between the pattern and the chosen materials. For instance, a pattern designed for a firmly stuffed, upright bear necessitates construction techniques that prioritize structural stability. Conversely, a pattern for a floppy, more poseable bear benefits from techniques that emphasize flexibility. The pattern itself may suggest specific techniques, but adaptability and understanding of various methods allow for creative interpretation and customization.

Mastery of appropriate construction techniques, therefore, represents a crucial link between the cloth teddy bear pattern and the realized creation. These techniques influence not only the structural integrity and aesthetic qualities of the finished toy but also the overall crafting experience. Choosing and implementing the appropriate construction methods ensures the successful translation of the two-dimensional pattern into a three-dimensional object that embodies the intended design, durability, and aesthetic qualities. Challenges may arise in matching technique to material or design complexity, highlighting the importance of careful consideration and adaptability throughout the construction process. Ultimately, the skillful application of construction techniques elevates the craft from a simple assembly of fabric pieces to a thoughtfully constructed, enduring keepsake.

5. Finishing Details

Finishing details represent the crucial final steps that transform a sewn assembly of fabric, based on a cloth teddy bear pattern, into a complete and characterful creation. These details, while seemingly minor, significantly impact the overall aesthetic, personality, and perceived quality of the finished toy. They bridge the gap between a basic construction and a cherished keepsake.

- Facial Features

Facial features imbue the teddy bear with personality and expressiveness. Embroidered eyes, noses, and mouths offer a classic, handcrafted aesthetic. The placement and style of these features significantly impact the bear’s perceived emotions and character. Safety eyes, while requiring careful attachment, provide a realistic gleam and contribute to the toy’s overall charm. These details often serve as focal points, drawing attention and enhancing the emotional connection between the toy and its owner. The cloth teddy bear pattern provides a basic framework for placement, but the crafter’s skill and interpretation during this finishing stage imbue the bear with unique personality.

- Embellishments

Embellishments, such as bows, ribbons, or clothing items, enhance the teddy bear’s visual appeal and personalize its presentation. A simple ribbon tied around the neck can add a touch of elegance, while a miniature outfit can transform the bear into a specific character. These additions, while not essential to the basic structure defined by the pattern, contribute to the toy’s overall aesthetic and perceived value. The selection and application of embellishments allow for creative expression and personalization beyond the confines of the pattern itself.

- Trimming and Shaping

Careful trimming and shaping of the fabric after stuffing refine the teddy bear’s silhouette and enhance its three-dimensional form. Trimming excess seam allowance prevents bulkiness and improves the overall neatness. Strategic shaping, through gentle manipulation and smoothing of the stuffing, ensures a well-defined and aesthetically pleasing final product. These finishing touches, while subtle, demonstrate attention to detail and contribute to the professional quality of the finished toy. They refine the raw construction dictated by the pattern into a polished and visually appealing creation.

- Joint Reinforcement

Reinforcing joints, particularly in areas subject to frequent movement or stress, enhances the teddy bear’s durability and longevity. Additional stitching or strategically placed interfacing strengthens these vulnerable areas, ensuring the bear can withstand regular handling and play. This attention to structural integrity during the finishing stage contributes to the toy’s long-term resilience and ensures it remains a cherished companion for years to come. This crucial step extends the lifespan of the crafted piece and contributes to its enduring value, transcending the limitations of the initial pattern instructions.

These finishing details, while often overlooked, represent crucial steps in transforming a cloth teddy bear pattern into a tangible, cherished object. They elevate the basic construction into a finished piece that reflects not only the pattern’s design but also the crafter’s skill and creative interpretation. The careful execution of these details contributes to the overall quality, aesthetic appeal, and lasting value of the finished teddy bear, demonstrating that true craftsmanship lies not only in following a pattern but also in the thoughtful execution of the finishing touches.

Frequently Asked Questions

This section addresses common inquiries regarding cloth teddy bear patterns, offering concise and informative responses to facilitate successful project completion.

Question 1: What types of fabric are most suitable for creating a teddy bear from a pattern?

Durable, tightly woven fabrics such as cotton twill, fleece, or minky are recommended. Fabric choice impacts both the final aesthetic and the ease of construction. Plush fabrics offer a softer feel, while tighter weaves provide a firmer structure.

Question 2: How does seam allowance affect the finished size of a teddy bear?

Seam allowance, the distance between the stitching line and the fabric edge, directly influences the final dimensions. Adhering to the specified seam allowance in the pattern ensures the intended size and proportions are achieved. Inconsistent seam allowance can result in a finished product that deviates from the pattern design.

Question 3: What are the essential tools required for constructing a teddy bear from a cloth pattern?

Essential tools include sharp fabric scissors, pins for securing pattern pieces, a sewing machine or needle and thread for hand-sewing, stuffing material such as fiberfill, and embroidery floss or other embellishments for facial features.

Question 4: What techniques are recommended for ensuring durable seams and joints?

Reinforced seams, achieved through backstitching or double stitching, enhance durability. Secure jointing methods, such as button joints or strongly sewn joints, contribute to a robust construction capable of withstanding regular handling.

Question 5: How can pattern size be adjusted without distorting the proportions of the teddy bear?

Pattern resizing requires uniform scaling of all pattern pieces. Enlarging or reducing each piece by the same percentage maintains the intended proportions and ensures a balanced final product.

Question 6: What safety considerations are relevant when selecting materials and constructing a teddy bear intended for a child?

Safety considerations include using non-toxic materials, ensuring all embellishments are securely attached, and avoiding small parts that could pose a choking hazard. Embroidered or safety eyes are preferable to buttons or other small detachable items.

Understanding these fundamental aspects contributes to successful project completion and a well-crafted finished product. Careful consideration of material selection, construction techniques, and safety precautions ensures a durable, aesthetically pleasing, and safe teddy bear.

Further exploration of specific techniques and design variations is presented in the following sections.

Conclusion

Templates for cloth teddy bears provide a foundational structure for crafting these cherished objects. Exploration of template design, fabric selection, seam allowance, construction techniques, and finishing details reveals the intricate interplay of these elements in achieving a successful outcome. Careful consideration of each aspect, from fabric properties to seam reinforcement, contributes to the final product’s durability, aesthetic appeal, and overall quality.

The enduring popularity of handcrafted teddy bears underscores the significance of these patterns as tools for creative expression and the preservation of traditional craft. Understanding the nuances within these seemingly simple templates empowers crafters to transform raw materials into cherished companions, imbued with individual character and enduring sentimental value. Continued exploration and refinement of these techniques promise a future rich with handcrafted creations, each bearing the unique mark of its creator.