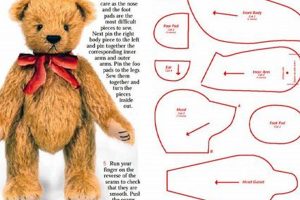

A plan or blueprint for constructing a stuffed toy bear from textiles provides crafters with the necessary dimensions, shapes, and instructions to create the final product. These plans can range from simple designs for beginners to complex, articulated patterns for experienced sewers. They typically include a materials list, cutting layouts, and step-by-step sewing guides, often accompanied by diagrams or photographs.

These resources are invaluable for ensuring consistent results and simplifying the creation process. They offer a structured approach, eliminating guesswork and enabling even novice crafters to produce professional-looking stuffed animals. Historically, such guides were hand-drawn and shared within crafting communities, but the advent of printing and digital media has broadened their accessibility, fostering creativity and the sharing of unique designs worldwide. The availability of these plans allows for a wider range of designs and complexity in finished products, contributing significantly to the enduring popularity of handmade toys.

This discussion will delve further into topics relevant to textile toy creation, encompassing material selection, construction techniques, and design variations, ultimately providing a comprehensive understanding of the art of bringing these cherished companions to life.

Tips for Utilizing Sewing Patterns for Stuffed Bears

Successful construction of a stuffed bear relies heavily on careful planning and execution. The following tips offer valuable insights into maximizing the effectiveness of a chosen design.

Tip 1: Fabric Selection is Crucial: The chosen textile significantly impacts the final appearance and durability. Consider the desired texture, pile, and drape. Closely woven fabrics are recommended for intricate details, while plush materials offer softness.

Tip 2: Precise Cutting is Essential: Accurate cutting ensures proper alignment and fit of the various components. Sharp shears and careful attention to the pattern markings are imperative. Using pattern weights can prevent shifting during the cutting process.

Tip 3: Markings Facilitate Assembly: Notches, dots, and other markings on the pattern pieces guide proper alignment during assembly. Transferring these markings accurately to the fabric ensures a symmetrical and well-constructed final product.

Tip 4: Seam Allowances Matter: Adhering to the specified seam allowance is critical for achieving the intended size and shape. Consistent seam allowances also contribute to a professional finish.

Tip 5: Appropriate Stitching Techniques Enhance Durability: Strong seams are essential for a toy subjected to regular handling. Backstitching at the beginning and end of seams reinforces stress points. Consider the type of seam best suited for each section, such as a ladder stitch for closing openings.

Tip 6: Stuffing Evenly Creates a Pleasing Form: Distributing the stuffing evenly throughout the bear’s body ensures a smooth, balanced appearance and prevents lumpiness. Pay close attention to extremities and joints.

Tip 7: Embellishments Add Personality: Features like embroidered eyes, noses, and mouths contribute to the bear’s unique character. Consider safety when selecting embellishments, particularly for toys intended for young children.

Adhering to these guidelines contributes significantly to a successful outcome, resulting in a well-constructed and aesthetically pleasing finished product. Careful consideration of materials, techniques, and details elevates the craft beyond mere assembly to a creative and rewarding experience.

These tips offer a starting point for creating a treasured handmade companion. Further exploration of specific techniques and materials will enrich one’s understanding and proficiency in this craft.

1. Pattern Design

Pattern design forms the foundational blueprint for a fabric teddy bear, dictating its final form, proportions, and complexity. A well-crafted design is crucial for achieving a desirable outcome, impacting every stage of the construction process.

- Shape and Silhouette:

The pattern defines the overall shape of the bear, from classic teddy bear silhouettes to more stylized or character-driven forms. This includes the proportions of the head, body, limbs, and any additional features like ears or a snout. A simple, rounded design might suit a beginner project, while a more complex, articulated pattern allows for greater poseability and detail.

- Seam Placement and Construction:

Strategic seam placement contributes not only to the bear’s structural integrity but also to its aesthetic appeal. The pattern dictates where seams are located, influencing the final three-dimensional form. Gussets, darts, and other shaping techniques integrated into the pattern pieces contribute to a more refined and lifelike appearance. Consideration of seam placement also impacts the ease of construction.

- Size and Scale:

Patterns are drafted to specific dimensions, determining the finished size of the bear. This can range from miniature bears suitable for keychains to large, huggable companions. Scaling a pattern requires careful recalculation of all measurements to maintain proper proportions.

- Detail and Articulation:

The level of detail within a pattern significantly influences the final product. Simple patterns may consist of basic shapes, while more advanced designs incorporate features like separate paw pads, defined joints, or embroidered details. Articulated patterns include design elements that allow for limb movement and poseability, often achieved through strategic joint placement and specialized construction techniques.

These interconnected facets of pattern design ultimately determine the character and complexity of the finished fabric teddy bear. Careful consideration of each element allows crafters to select or create designs that align with their skill level and desired outcome, ensuring a satisfying and rewarding crafting experience. A thorough understanding of the pattern’s intricacies lays the groundwork for successful execution and a well-crafted final product.

2. Fabric Choice

Fabric choice plays a pivotal role in the successful execution of a fabric teddy bear sewing pattern. The selected textile directly impacts not only the final aesthetic of the bear but also its durability, construction process, and overall character. The pattern itself often provides recommendations for suitable fabrics, taking into account factors such as the complexity of the design and the desired finished look. A mismatch between pattern and fabric can lead to construction challenges or an unsatisfactory final result.

The interplay between fabric and pattern manifests in several key ways. A pattern intended for woven cotton, for example, might not drape or gather correctly if constructed from a stretchy knit fabric. Conversely, a pattern designed for a plush, high-pile fabric might lose crucial details if made from a flat, densely woven material. Practical considerations also come into play. A pattern with intricate details requires a fabric that holds its shape well during sewing and allows for precise cutting. A robust, tightly woven fabric is often preferred for high-wear areas like joints and paws. For a softer, more cuddly bear, plush fabrics with longer piles are chosen, but these can require specialized sewing techniques to manage the bulk and prevent shedding. Real-world examples include using mohair for a traditional, heirloom-quality bear, or employing fleece for a more contemporary, washable toy.

Understanding the crucial relationship between fabric choice and pattern design is essential for achieving desired results. Careful consideration of texture, drape, durability, and ease of sewing, informed by the pattern’s recommendations, ensures a successful outcome. Failure to acknowledge this connection can lead to difficulties during construction, compromise the structural integrity of the finished bear, or result in a final product that doesn’t meet expectations. This understanding empowers crafters to make informed decisions, ultimately leading to a more satisfying and well-executed project.

3. Seam allowance

Seam allowance, the fabric width between the raw edge and the stitching line, represents a critical element within a fabric teddy bear sewing pattern. Its specified measurement directly influences the final dimensions and structural integrity of the finished piece. Patterns explicitly state the required seam allowance, typically ranging from inch to inch. Adhering to this specified measurement is crucial; deviations can result in a bear that is either too large or too small, with distorted proportions. For instance, consistently using a larger seam allowance than specified will result in smaller pattern pieces and a smaller finished bear. Conversely, a smaller seam allowance yields larger pieces and a larger final product. This principle holds true for all pattern components, impacting the fit of the head, body, limbs, and other features.

Beyond size, seam allowance impacts durability. An inadequate seam allowance leaves minimal fabric for securing seams, increasing the risk of tearing, especially in high-stress areas like joints. Sufficient seam allowance provides a robust foundation for stitching, contributing to the longevity of the toy. Furthermore, maintaining a consistent seam allowance ensures proper alignment of pattern pieces during assembly. Inconsistent seam allowances can introduce distortions, making it difficult to achieve a symmetrical and well-constructed final product. Consider a curved seam, like the one joining a bear’s head to its body; variations in the seam allowance along this curve will impede smooth joining, resulting in puckering or gaps. The practical significance of understanding seam allowance becomes evident during the construction process. Precise cutting and stitching, guided by the pattern’s specified seam allowance, are essential for achieving the intended design and ensuring a well-crafted, durable teddy bear.

In summary, seam allowance represents a fundamental aspect of fabric teddy bear sewing patterns. Its correct application impacts not only the final size and shape but also the structural integrity and overall quality of the finished bear. Precise adherence to the specified seam allowance ensures proper fit, enhances durability, and facilitates accurate assembly, ultimately contributing to a successful and satisfying crafting experience. Challenges arise when seam allowance is misunderstood or inconsistently applied, underscoring the importance of this seemingly small detail within the larger context of teddy bear construction.

4. Cutting accuracy

Cutting accuracy represents a critical link between the two-dimensional representation of a fabric teddy bear sewing pattern and the three-dimensional realization of the finished toy. The precision with which pattern pieces are cut directly impacts the final size, shape, and overall construction quality of the bear. Deviations from the pattern’s outlines introduce inaccuracies that can compound during assembly, leading to a finished product that differs significantly from the intended design. The pattern serves as a blueprint, and accurate cutting ensures that each component adheres to the prescribed dimensions and shapes. Cause and effect are clearly demonstrable: precise cutting yields components that fit together seamlessly, while inaccurate cutting results in misaligned seams, distorted shapes, and a compromised final product. Consider, for example, cutting the curved pieces for a bear’s head. Imprecise cutting along these curves will result in a head that is either too large or too small, impacting the overall proportions and potentially making it difficult to attach to the body.

The importance of cutting accuracy as a component of a fabric teddy bear sewing pattern cannot be overstated. It forms the foundation upon which successful construction is built. While subsequent steps like sewing and stuffing can mitigate minor cutting inaccuracies to some extent, significant deviations can create insurmountable challenges, necessitating recutting or even abandoning the project altogether. Think of assembling a puzzle; if the individual pieces are not cut correctly, they will not fit together to form the complete picture. Similarly, inaccurate cutting of fabric pieces compromises the integrity of the pattern’s design, impacting the bear’s final form and potentially affecting its structural stability. Practical application of this principle involves careful attention to detail during the cutting process. Sharp shears, precise placement of the pattern pieces on the fabric, and adherence to the cutting lines are essential. Using pins or pattern weights to secure the pattern to the fabric prevents shifting and ensures accurate cutting. Furthermore, understanding the fabric’s grain and directional nap is crucial for achieving the intended drape and appearance of the finished bear.

In summary, cutting accuracy serves as a cornerstone of successful teddy bear construction. It translates the two-dimensional pattern into three-dimensional form with fidelity, ensuring that the finished product reflects the intended design. Challenges arise when cutting accuracy is compromised, potentially leading to construction difficulties, distorted proportions, and a compromised final product. This underscores the critical connection between precise cutting and the realization of a well-crafted fabric teddy bear from its pattern blueprint. The practical significance of this understanding empowers crafters to approach the cutting process with the necessary care and attention, maximizing the likelihood of a successful and satisfying outcome.

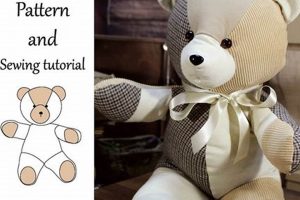

5. Assembly Instructions

Assembly instructions within a fabric teddy bear sewing pattern serve as the roadmap guiding the transformation of individual fabric components into a cohesive, three-dimensional form. These instructions provide a sequential, step-by-step process for joining the various pattern pieces, dictating not only the order of assembly but also the specific sewing techniques required for each stage. The clarity and precision of these instructions directly influence the ease of construction and the accuracy of the final result. A well-written set of instructions facilitates a smooth, efficient assembly process, minimizing potential errors and ensuring a finished product that aligns with the pattern’s design. Conversely, ambiguous or incomplete instructions can lead to confusion, frustration, and ultimately, a compromised final product. Cause and effect are evident: clear instructions lead to successful construction, while inadequate instructions increase the likelihood of errors and an unsatisfactory outcome. A real-world example would be the instructions for attaching the bear’s head to its body. Clear instructions would specify the type of seam to use, the placement of the head relative to the body, and any specific techniques required for achieving a smooth and secure join.

The importance of assembly instructions as a component of a fabric teddy bear sewing pattern cannot be overstated. They provide the critical link between the pattern’s individual components and the realization of a complete, well-constructed toy. The instructions often incorporate diagrams or photographs to visually reinforce the written steps, further clarifying the assembly process. They may also include tips for specific techniques, such as how to create a ladder stitch for closing openings or how to evenly distribute stuffing for a smooth, balanced form. The practical significance of understanding and following these instructions is paramount. Deviation from the prescribed sequence or the application of incorrect techniques can lead to structural weaknesses, misaligned seams, and an overall compromised aesthetic. Imagine, for instance, attaching the bear’s limbs before closing the body seams. This would create significant challenges for turning the bear right-side out and stuffing it correctly. Such an error underscores the importance of following the assembly instructions meticulously.

In summary, assembly instructions form an integral part of a fabric teddy bear sewing pattern. They translate the two-dimensional pattern pieces into a three-dimensional form through a clear, sequential process. The clarity, accuracy, and completeness of these instructions directly impact the ease of construction and the quality of the finished product. Challenges arise when instructions are poorly written, misunderstood, or disregarded, highlighting the crucial role they play in successfully realizing a well-crafted fabric teddy bear from its pattern blueprint. A thorough understanding of the assembly instructions, coupled with careful execution, empowers crafters to navigate the construction process with confidence, resulting in a finished product that reflects the pattern’s intended design and provides lasting enjoyment.

6. Finishing techniques

Finishing techniques represent the crucial final steps in bringing a fabric teddy bear sewing pattern to life, elevating the project from a sewn assembly of components to a polished, professional-looking creation. These techniques encompass a range of procedures, including closing seams, turning the bear right-side out, stuffing, closing the stuffing opening, adding facial features, and attaching embellishments. Each technique contributes significantly to the overall aesthetic and durability of the finished bear. The connection between finishing techniques and the pattern is integral; the pattern often dictates specific techniques suited to the design and the chosen fabrics. Cause and effect are demonstrably linked: meticulous finishing techniques result in a refined and durable toy, while hasty or improper techniques compromise the final product’s appearance and longevity. A real-world example is the invisible ladder stitch used for closing the stuffing opening. This technique creates a nearly seamless closure, minimizing visibility and enhancing the professional finish.

The importance of finishing techniques as a component of a fabric teddy bear sewing pattern is paramount. They represent the culmination of the construction process, transforming the assembled pieces into a finished, presentable object. Properly executed finishing techniques enhance not only the visual appeal but also the tactile quality and overall durability of the bear. For instance, carefully sculpting the facial features during stuffing and strategically placing embellishments contribute significantly to the bear’s personality and charm. Furthermore, secure stitching and proper closure techniques ensure that the stuffing remains contained and that the seams withstand regular handling. The practical significance of understanding and applying these techniques is evident in the final product. A well-finished bear exhibits a level of craftsmanship that distinguishes it from a hastily assembled toy. Consider the difference between a neatly embroidered nose and a clumsily attached button; the former enhances the bear’s character, while the latter detracts from its overall appearance.

In summary, finishing techniques constitute the essential final steps in realizing a well-crafted fabric teddy bear from its pattern. These techniques, ranging from seam closure to embellishment attachment, directly impact the final appearance, durability, and overall quality of the finished piece. Challenges arise when finishing techniques are overlooked or improperly executed, underscoring their crucial role in the overall construction process. A thorough understanding and meticulous application of these techniques elevate the project from a simple assembly of fabric pieces to a polished, cherished creation, reflecting the crafter’s skill and attention to detail. This understanding allows crafters to fully realize the potential of the fabric teddy bear sewing pattern, resulting in a finished product that embodies both craftsmanship and artistry.

7. Embellishment Options

Embellishment options represent the final flourishes within a fabric teddy bear sewing pattern, providing opportunities to personalize and imbue the finished creation with unique character. These options, ranging from embroidered facial features and decorative bows to clothing and accessories, transform the basic bear structure into a distinct individual. The connection between embellishment options and the sewing pattern is often symbiotic; the pattern may suggest specific embellishments that complement the design, while the chosen embellishments can influence the overall aesthetic and perceived character of the finished bear. Cause and effect are intertwined: thoughtful embellishment choices enhance the bear’s personality and appeal, while ill-suited or poorly executed embellishments can detract from the overall design. Embroidered eyes, for example, can convey a range of emotions, from playful mischief to gentle warmth, depending on their shape, size, and placement. A simple ribbon tied around the neck adds a touch of elegance, while a miniature hand-knitted sweater creates a sense of homespun charm.

Embellishment options hold significant weight within the broader context of a fabric teddy bear sewing pattern. They offer crafters the freedom to express creativity and personalize their creations. The pattern may provide guidance on embellishment placement and techniques, ensuring that these additions enhance rather than detract from the overall design. This guidance can include suggestions for embroidery stitches, fabric paint application, or the secure attachment of buttons and other decorative elements. Practical considerations also come into play. Embellishments for children’s toys must adhere to safety standards, avoiding small, detachable parts that could pose a choking hazard. The choice of embellishments can also influence the care instructions for the finished bear; delicate embellishments may require hand-washing or special cleaning methods. The practical application of this understanding allows crafters to make informed decisions, selecting embellishments that align with the intended purpose and recipient of the bear. A bear intended as a nursery decoration might feature pastel ribbons and delicate embroidery, while a bear designed for a child’s playmate might incorporate durable buttons and brightly colored fabrics.

In summary, embellishment options represent a powerful tool within the fabric teddy bear sewing pattern framework. These options allow for creative expression, personalization, and the imbuement of unique character into the finished creation. The careful selection and application of embellishments, guided by the pattern’s suggestions and practical considerations, elevate the finished product from a simple sewn toy to a cherished keepsake. Challenges arise when embellishment choices clash with the overall design or compromise the bear’s safety or durability, underscoring the importance of thoughtful consideration and skillful execution. This understanding empowers crafters to fully utilize embellishment options to enhance their creations, resulting in fabric teddy bears that are not only well-crafted but also imbued with personality and charm.

Frequently Asked Questions

This section addresses common inquiries regarding fabric teddy bear sewing patterns, providing concise and informative responses to facilitate a deeper understanding and enhance the crafting experience.

Question 1: What are the essential tools required for utilizing a fabric teddy bear sewing pattern?

Essential tools include sharp fabric shears, pins or pattern weights, a sewing machine or needle and thread, stuffing material, embroidery floss or other embellishments, and a seam ripper for correcting errors.

Question 2: How does one choose an appropriate fabric for a teddy bear project?

Fabric selection depends on the desired aesthetic and durability. Plush fabrics like mohair or fleece offer softness, while tightly woven cottons or linens provide a firmer structure. The pattern often provides specific fabric recommendations.

Question 3: What is the significance of seam allowance in teddy bear construction?

Seam allowance, the distance between the raw edge and the stitching line, directly impacts the final size and structural integrity of the bear. Adhering to the pattern’s specified seam allowance is crucial for achieving proper proportions and preventing seam failure.

Question 4: What techniques are employed for creating durable seams in a teddy bear?

Durable seams are achieved through techniques like backstitching at the beginning and end of seams, using strong thread appropriate for the fabric, and selecting seam types suited to the specific application, such as ladder stitch for closing openings.

Question 5: How can one ensure even stuffing distribution within a teddy bear?

Even stuffing distribution requires small amounts of stuffing added incrementally, carefully shaping and compacting the material into all areas, paying particular attention to extremities and joints to prevent lumpiness and achieve a smooth, balanced form.

Question 6: What safety considerations are relevant when selecting embellishments for a teddy bear intended for a young child?

Safety considerations include avoiding small, detachable parts that could pose a choking hazard. Securely attaching embellishments and opting for embroidered features over glued-on elements enhance safety and longevity.

Understanding these fundamental aspects of working with fabric teddy bear sewing patterns contributes significantly to a successful and rewarding crafting experience, resulting in a well-constructed and cherished creation.

This concludes the frequently asked questions section. Further exploration of specific techniques and design variations will deepen one’s understanding and proficiency in the art of teddy bear creation.

Fabric Teddy Bear Sewing Pattern

Exploration of the fabric teddy bear sewing pattern reveals its multifaceted nature as a blueprint for creation. From the initial selection of an appropriate design and fabric to the meticulous execution of construction and finishing techniques, each element plays a crucial role in the realization of a finished piece. Pattern design dictates form and complexity. Fabric choice impacts aesthetics and durability. Accurate cutting and adherence to specified seam allowances ensure proper fit and structural integrity. Clear assembly instructions guide the construction process, while careful application of finishing techniques elevates the final product. Embellishment choices provide opportunities for personalization and imbue the creation with unique character. A comprehensive understanding of these interconnected elements is essential for achieving a successful outcome.

The enduring appeal of the handmade teddy bear transcends mere craftsmanship; it represents a tangible expression of creativity and care. The fabric teddy bear sewing pattern, in its various forms, serves as a conduit for this expression, enabling crafters to transform raw materials into cherished companions. Continued exploration of design variations, material innovations, and construction techniques promises a vibrant future for this timeless craft, ensuring that the creation of handmade teddy bears remains a source of both personal fulfillment and enduring joy for generations to come.