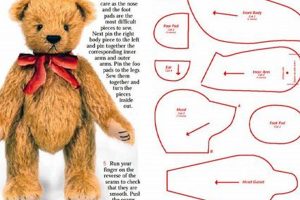

A template for crafting a stuffed toy usually consists of individual fabric pieces, strategically shaped and sized to be sewn together. These templates can range from simple designs for beginners to intricate, complex patterns for experienced sewers. Often, these templates are printed on paper or cardstock, sometimes accompanied by detailed instructions and illustrations. A well-drafted template ensures the final product holds its intended form and proportions.

Precise templates are essential for achieving a well-constructed and aesthetically pleasing result. They provide a guide for cutting fabric accurately, minimizing waste and maximizing efficiency. Historically, these guides were often hand-drawn and passed down through generations, playing a significant role in the craft of toymaking. Today, readily available templates facilitate creativity and enable crafters of all skill levels to produce charming handmade toys.

This detailed guide will explore various aspects of template selection and utilization, encompassing fabric choices, sewing techniques, and finishing touches. Further sections will delve into specific design considerations, offering guidance for both novice and advanced creators.

Tips for Utilizing Teddy Bear Templates

Careful consideration of several factors contributes significantly to the successful execution of a teddy bear project from a template.

Tip 1: Fabric Selection: Opting for appropriate fabric is paramount. Durable materials such as mohair, fleece, or cotton are recommended for long-lasting results. The fabric’s texture and weight should complement the desired aesthetic and intended use of the finished bear.

Tip 2: Accurate Cutting: Precise cutting along template lines is crucial for proper assembly. Sharp scissors and careful attention to detail ensure clean edges and minimize discrepancies in piece sizes, leading to a more polished final product.

Tip 3: Marking and Notching: Transferring markings from the template to the fabric, including notches and darts, aids in proper alignment during sewing. These markings serve as crucial guides for creating accurate seams and shaping the bear’s features.

Tip 4: Seam Allowance Consistency: Maintaining a consistent seam allowance is vital for achieving the intended size and shape of the finished bear. Variations in seam allowance can lead to misaligned pieces and a distorted final form.

Tip 5: Proper Stuffing Technique: Distributing stuffing evenly throughout the bear’s body creates a smooth, professional appearance. Overstuffing can strain seams, while understuffing can result in a limp and unappealing form.

Tip 6: Secure Closures: Ensuring secure closures for stuffing openings prevents leakage and maintains the bear’s integrity over time. Hidden seams or ladder stitches provide discreet and durable closures.

Tip 7: Embellishment Considerations: Adding embellishments such as eyes, noses, and mouths should be undertaken with care. Securely fastened features enhance the bear’s aesthetic appeal and ensure long-term durability.

Adhering to these guidelines contributes significantly to a successful outcome. Precise cutting, careful stitching, and thoughtful material selection are fundamental to creating a well-crafted, enduring teddy bear.

By understanding and applying these techniques, one can elevate a simple template into a cherished handmade creation.

1. Template Choice

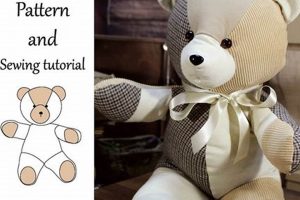

Template choice represents a pivotal decision in the process of crafting a teddy bear. The template, serving as the foundational blueprint, directly determines the final form, size, and complexity of the finished product. This choice influences not only the bear’s aesthetic qualities but also the technical skills and time commitment required for construction. A simple, beginner-friendly template might involve basic shapes and minimal sewing, resulting in a classic teddy bear design. Conversely, a complex, articulated template featuring intricate details and numerous components yields a more sophisticated, poseable bear, demanding advanced sewing proficiency. The template effectively dictates the project’s trajectory, impacting material requirements, construction techniques, and ultimately, the final character of the bear. For instance, a template designed for mohair fabric might incorporate specific seam allowances and construction details optimized for that material’s unique properties, whereas a template intended for fleece might necessitate different considerations.

Template selection also impacts the creative potential within the project. While some templates offer limited room for customization, others provide opportunities for personalization through modifications to limb length, head shape, or overall proportions. This flexibility allows experienced crafters to express individual artistry and create unique, personalized teddy bears. The chosen template further impacts the integration of additional features, such as embroidered details, clothing, or accessories. A template designed for a jointed bear will naturally lend itself to more dynamic posing and interactive play, while a simpler, non-jointed template might prioritize a softer, more cuddly feel. Therefore, understanding the nuances of template choice is crucial for aligning the project’s goals with the desired outcome.

Effective template selection streamlines the construction process, minimizing potential challenges and maximizing the likelihood of a successful outcome. A well-designed template provides clear instructions, accurate measurements, and appropriate seam allowances, reducing the risk of errors during cutting and assembly. This clarity is particularly important for novice crafters, enabling them to build confidence and develop essential skills. Ultimately, the choice of template functions as the cornerstone of the entire project, influencing every subsequent step, from material selection to finishing touches. A thorough understanding of template options empowers crafters to make informed decisions, aligning their skills and creative vision with the desired outcome, whether it be a simple, classic teddy bear or a complex, character-filled creation.

2. Fabric Type

Fabric selection significantly impacts the final appearance, durability, and construction process of a teddy bear. The chosen fabric must complement the design intent of the template and meet the desired tactile and aesthetic qualities. Fabric properties, such as texture, weight, and stretch, directly influence the bear’s form, drape, and longevity. A considered choice ensures the successful execution of the template and the creation of a well-crafted, enduring final product.

- Texture

Texture plays a crucial role in the overall aesthetic and tactile experience of the finished bear. Plush fabrics like mohair or alpaca create a soft, luxurious feel, while shorter pile fabrics like fleece offer a smooth, cuddly texture. The texture interacts with light, influencing the bear’s visual appearance, and dictates how the finished product feels in hand. A textured fabric might require specific construction techniques outlined in the template to maximize its visual appeal and prevent unwanted distortion during assembly.

- Weight

Fabric weight influences the bear’s drape and overall structure. Heavier fabrics, like dense wool or fur, create a more substantial, robust form, while lighter fabrics, such as cotton or linen, result in a softer, more pliable feel. Template choice should consider fabric weight to ensure proper construction. A template intended for a lighter weight fabric might require adjustments if used with a heavier material to maintain the intended shape and proportions. Weight also affects the ease of sewing and the durability of the finished product.

- Stretch

The fabric’s stretch factor affects how well it conforms to the template’s curves and contours. Stretchy fabrics, such as knit or jersey materials, require careful handling during construction to avoid distortion. Conversely, non-stretch fabrics, like woven cotton or linen, provide more structural integrity and hold their shape well. The template instructions typically address stretch considerations, offering guidance on cutting and sewing techniques to ensure proper fit and prevent puckering or stretching during assembly.

- Durability

Durability is a critical factor, especially for bears intended for frequent handling or play. Robust fabrics like canvas or denim offer greater resistance to wear and tear, while delicate fabrics like silk or satin require more careful handling. Template choice might recommend specific fabric types based on the anticipated use of the finished bear. Additionally, the chosen fabric’s durability influences the longevity of the finished product and its ability to withstand repeated use and cleaning.

Careful consideration of these fabric properties ensures compatibility with the chosen template and contributes significantly to the overall success of the project. A well-chosen fabric enhances the aesthetic qualities, structural integrity, and longevity of the finished teddy bear, transforming a simple pattern into a cherished, enduring creation. Ignoring these factors can lead to construction challenges, an unsatisfactory final appearance, and a less durable finished product. Therefore, aligning fabric type with the template’s specifications and the intended purpose of the teddy bear is paramount.

3. Seam Allowance

Seam allowance, the fabric width between the raw edge and the stitching line, represents a critical element within the construction of a teddy bear from a pattern. Accurate and consistent seam allowance is fundamental to achieving the intended size, shape, and structural integrity of the finished product. Its role extends beyond simply joining fabric pieces; it directly influences the bear’s proportions, the fit of individual components, and the overall aesthetic. Mismanagement of seam allowance can lead to discrepancies between the pattern’s design and the realized form, potentially compromising the bear’s appearance and durability.

- Dimensional Accuracy

The specified seam allowance on a pattern dictates the final dimensions of each component and, consequently, the overall size of the finished bear. Adhering to the prescribed seam allowance ensures that individual pieces align correctly during assembly and contribute to the intended proportions. Deviating from the designated seam allowance can result in a bear that is either smaller or larger than intended, potentially affecting the fit of limbs, the closure of seams, and the overall balance of the design. For example, a smaller seam allowance than specified might create a larger finished product, while a larger seam allowance could result in a smaller, tighter fit.

- Structural Integrity

Seam allowance contributes significantly to the structural integrity of the finished bear. Adequate seam allowance provides sufficient fabric for secure stitching and durable seams. Insufficient seam allowance can lead to weak seams prone to fraying or tearing, especially under stress. Conversely, excessive seam allowance can create bulky seams, distorting the bear’s shape and potentially interfering with the smooth flow of the fabric. For instance, a narrow seam allowance on a curved seam might cause the fabric to pucker or strain, weakening the seam and affecting the bear’s appearance.

- Aesthetic Impact

Seam allowance, while primarily a functional element, also impacts the aesthetic qualities of the finished bear. Consistent seam allowances contribute to clean, professional-looking seams and a polished final appearance. Uneven seam allowances can create visible irregularities, disrupting the smooth lines of the design and detracting from the overall aesthetic. For instance, varying seam allowances around the head or limbs can create an uneven, unprofessional finish.

- Ease of Assembly

The designated seam allowance on a pattern influences the ease of assembly. A clearly marked and consistent seam allowance simplifies the sewing process, allowing for accurate alignment of fabric pieces and efficient construction. Inconsistent or unclear seam allowance markings can complicate the assembly process, leading to frustration and potential errors. For example, a pattern with a clearly marked -inch seam allowance facilitates straightforward sewing, while a pattern lacking clear markings or with inconsistent allowances can lead to misaligned pieces and a more challenging construction process.

Therefore, understanding and meticulously adhering to the specified seam allowance on a teddy bear pattern is essential for achieving a well-constructed, aesthetically pleasing, and durable finished product. Seam allowance represents a critical factor that directly influences the bear’s final dimensions, structural integrity, and overall appearance. Its careful management contributes significantly to the successful execution of the pattern and the realization of the intended design.

4. Cutting Accuracy

Cutting accuracy represents a critical factor in successfully utilizing a teddy bear pattern. Precise cutting along designated lines directly influences the final product’s quality and the seamless execution of the design. Inaccuracies introduced during the cutting phase propagate through the assembly process, potentially leading to misaligned seams, distorted shapes, and an overall compromised final product. The pattern serves as a blueprint, and precise cutting ensures the faithful realization of that blueprint in fabric form. For example, inaccurate cutting of curved sections, such as the bear’s head or limbs, can result in noticeable irregularities in the finished product. Similarly, imprecise cutting of straight edges can compromise the alignment of seams and affect the overall symmetry of the bear.

The importance of cutting accuracy extends beyond mere aesthetics. It directly impacts the structural integrity of the finished bear. Properly cut pieces fit together seamlessly, allowing for strong, even seams. In contrast, inaccurately cut pieces can lead to strained seams, weak points, and a less durable finished product. Consider a pattern with notched markings for aligning specific points. Inaccurate cutting around these notches compromises their function, leading to misaligned pieces and potentially distorted features. This highlights the crucial role of precise cutting in ensuring the proper fit and structural soundness of the bear.

Achieving cutting accuracy requires careful attention to detail and the appropriate tools. Sharp scissors designed for fabric cutting are essential for clean, precise cuts. Rotary cutters coupled with cutting mats offer enhanced accuracy, particularly for complex shapes and multiple layers of fabric. Furthermore, careful pinning and securing of the pattern pieces to the fabric minimize shifting and ensure adherence to the designated cutting lines. The connection between cutting accuracy and the successful utilization of a teddy bear pattern is undeniable. Precise cutting ensures the accurate translation of the pattern’s design into a well-constructed, aesthetically pleasing, and durable finished product. This foundational step in the construction process sets the stage for a successful outcome and minimizes potential complications during assembly.

5. Marking Clarity

Marking clarity within a teddy bear pattern constitutes a crucial element for successful construction. Clear, precise markings guide the assembly process, ensuring accurate alignment, proper shaping, and the realization of the intended design. These markings serve as a roadmap, translating the two-dimensional pattern into a three-dimensional form. Their clarity directly influences the ease of construction, the accuracy of component assembly, and the overall quality of the finished teddy bear.

- Notches

Notches, small marks along seam lines, indicate points of alignment between pattern pieces. Precisely placed and clearly marked notches facilitate accurate joining of fabric components, ensuring proper fit and preventing misalignment. For instance, notches along a curved seam, such as the bear’s armhole, guide the sewer in aligning the arm to the body, ensuring a smooth, properly shaped joint. Clear notch markings minimize the risk of mismatched seams and contribute to the overall structural integrity of the bear.

- Darts

Darts, triangular folds sewn into the fabric, create shape and contour. Clearly marked darts, indicated by lines and points on the pattern, guide the sewer in creating these shaping elements. Accurate dart placement is essential for achieving the desired three-dimensional form, such as the curvature of the bear’s head or the definition of its limbs. Precisely sewn darts, guided by clear markings, enhance the bear’s realism and aesthetic appeal.

- Grainlines

Grainlines, indicated by arrows on the pattern, denote the direction of the fabric’s weave. Aligning pattern pieces with the fabric’s grainline ensures that the finished product drapes correctly and maintains its shape over time. Clearly marked grainlines guide fabric placement, minimizing stretching or distortion during construction and contributing to the long-term integrity of the bear. Ignoring grainline markings can lead to a finished product that hangs unevenly or loses its shape over time.

- Placement Lines for Embellishments

Placement lines for embellishments, such as eyes, noses, and mouths, guide their accurate positioning. Clearly marked placement lines ensure symmetrical features and enhance the bear’s overall aesthetic. These markings contribute to a professional-looking finished product, avoiding asymmetry or misplaced features that can detract from the bear’s appearance. For example, clearly marked placement lines for the eyes ensure they are evenly spaced and aligned, contributing to the bear’s expressiveness and charm.

The clarity of these markings directly correlates with the ease and accuracy of constructing a teddy bear from a pattern. Well-defined markings streamline the assembly process, minimizing the potential for errors and ensuring a successful outcome. In essence, clear markings empower the crafter to translate the two-dimensional pattern into a well-constructed, three-dimensional teddy bear that accurately reflects the intended design.

6. Assembly Instructions

Assembly instructions constitute a critical component of a teddy bear pattern, providing a roadmap for transforming individual fabric pieces into a cohesive, three-dimensional form. These instructions bridge the gap between the two-dimensional pattern and the finished product, guiding the construction process through a logical sequence of steps. The clarity, comprehensiveness, and accuracy of these instructions directly impact the ease of assembly, the accuracy of the final product, and the overall success of the project. A well-crafted set of instructions ensures a smooth, efficient construction process, while poorly written or incomplete instructions can lead to confusion, errors, and a compromised final product. For instance, a pattern lacking clear instructions on joining the bear’s head to its body can result in misalignment, instability, and a less aesthetically pleasing result.

The effectiveness of assembly instructions lies in their ability to communicate complex construction processes in a clear, concise, and accessible manner. Effective instructions often employ a combination of textual descriptions, diagrams, and illustrations to convey the necessary information. Visual aids, such as step-by-step illustrations or exploded diagrams, can significantly enhance understanding, particularly for complex assembly steps. Consider a pattern incorporating an intricate jointing mechanism for the bear’s limbs. Clear diagrams illustrating the correct placement and attachment of the joints prove invaluable in ensuring proper functionality and preventing errors during assembly. The sequence of assembly steps also plays a crucial role. A logical progression, starting with basic construction and moving towards more complex elements, facilitates a smoother, more manageable process. For example, instructions typically guide the construction of the bear’s head and body before proceeding to the attachment of limbs and other details.

Comprehensive assembly instructions address various aspects of the construction process, including seam types, stitching techniques, stuffing methods, and finishing details. Clear guidance on appropriate seam types, such as backstitching for structural seams or whipstitching for closing openings, ensures the durability and aesthetic quality of the finished product. Detailed instructions on stuffing techniques, including the type and amount of stuffing material, contribute to the bear’s proper form and shape. Furthermore, comprehensive instructions address finishing details, such as attaching eyes, noses, and other embellishments, enhancing the bear’s overall character and appeal. The absence of clear instructions on these aspects can lead to structural weaknesses, an unprofessional finish, and a less satisfactory final product. Ultimately, well-crafted assembly instructions empower crafters to successfully navigate the complexities of teddy bear construction, transforming a pattern into a cherished, well-crafted creation.

7. Finishing Techniques

Finishing techniques represent the crucial final steps in bringing a teddy bear pattern to life, transforming a sewn construction into a characterful, complete creation. These techniques, though seemingly minor, significantly impact the bear’s overall aesthetic, durability, and perceived quality. The connection between finishing techniques and the pattern is integral; the pattern often dictates specific finishing approaches to achieve the intended design. For example, a pattern designed for a jointed teddy bear will necessitate specific finishing techniques for attaching and securing the joints, ensuring proper functionality and durability. Conversely, a pattern for a simpler, non-jointed bear might emphasize finishing techniques that prioritize softness and cuddliness.

Consider the process of closing the final seam after stuffing. A poorly executed closure can detract from the bear’s appearance and compromise its structural integrity. Techniques like ladder stitching, an invisible stitch that seamlessly closes the opening, demonstrate the impact of careful finishing. Similarly, the method of attaching facial features, such as eyes and noses, significantly influences the bear’s expressiveness and character. Securely fastened, well-placed features enhance the bear’s aesthetic appeal, while loosely attached or misaligned features can detract from the overall design. The type of thread used for these attachments also plays a role; a strong, durable thread ensures longevity, while a weak thread can lead to detached features and a compromised final product. These examples illustrate the practical significance of understanding the interplay between finishing techniques and the pattern itself.

The choice and execution of finishing techniques directly influence the final realization of the teddy bear pattern. Techniques such as brushing and sculpting the bear’s fur, trimming seams, and adding decorative elements like ribbons or clothing contribute to the bear’s unique personality and aesthetic appeal. These seemingly small details elevate the finished product from a simple sewn object to a cherished, handcrafted creation. Challenges in finishing often arise from a lack of attention to detail or a misunderstanding of the techniques required by the specific pattern. Addressing these challenges requires careful study of the pattern instructions, practice, and a willingness to refine techniques over time. Ultimately, mastering finishing techniques elevates the craft of teddy bear making, ensuring the successful realization of the pattern’s design and the creation of a truly unique and enduring piece.

Frequently Asked Questions

This section addresses common inquiries regarding teddy bear pattern utilization, offering concise and informative responses to facilitate successful project completion.

Question 1: What are the essential tools required for utilizing a teddy bear pattern?

Essential tools include sharp fabric scissors, pins, a seam ripper, a measuring tape, marking tools (such as tailor’s chalk or a fabric marker), and a sewing machine or needle and thread for hand-sewing. Specialized tools like rotary cutters and cutting mats can enhance precision, particularly for intricate patterns.

Question 2: How does one choose an appropriate fabric for a teddy bear pattern?

Fabric selection depends on the desired aesthetic and intended use. Durable fabrics like mohair, fleece, or cotton are generally recommended. Consider the fabric’s texture, weight, and stretch, ensuring compatibility with the pattern’s specifications.

Question 3: What is the significance of seam allowance in teddy bear construction?

Seam allowance, the fabric width between the raw edge and the stitching line, is crucial for accurate sizing and structural integrity. Maintaining consistent seam allowances, as specified in the pattern, ensures proper fit and prevents distortions.

Question 4: How does one address challenges related to intricate pattern details or complex assembly steps?

Consulting online resources, such as video tutorials or crafting forums, can provide valuable guidance. Additionally, seeking assistance from experienced crafters can offer personalized support for navigating complex techniques.

Question 5: What are common mistakes to avoid when using a teddy bear pattern?

Common mistakes include inaccurate cutting, inconsistent seam allowances, and neglecting pattern markings. Careful attention to detail and adherence to the pattern instructions minimize these errors.

Question 6: What resources are available for individuals seeking further guidance on teddy bear pattern utilization?

Numerous online resources offer comprehensive information, including detailed tutorials, pattern reviews, and community forums. Craft books and local sewing classes provide additional avenues for skill development.

Careful consideration of these frequently asked questions facilitates a deeper understanding of teddy bear pattern utilization, contributing to successful project execution and the creation of cherished handmade companions.

The following section will explore advanced techniques for customizing teddy bear patterns, enabling further creative expression and personalization.

Conclusion

Templates for constructing teddy bears provide a foundational framework, impacting the final product’s form, structure, and aesthetic. Successful utilization necessitates careful consideration of factors such as fabric selection, seam allowance adherence, cutting accuracy, and the interpretation of pattern markings. Finishing techniques represent the crucial final steps, transforming sewn components into a complete, characterful creation. Understanding the interplay of these elements is essential for achieving desired outcomes and maximizing creative potential.

The enduring appeal of handmade teddy bears underscores the significance of these foundational principles. Precise execution of template instructions empowers crafters to produce cherished keepsakes, embodying creativity, craftsmanship, and enduring sentimental value. Continued exploration of these techniques enables further refinement and the realization of increasingly complex and personalized designs, perpetuating the timeless craft of teddy bear creation.