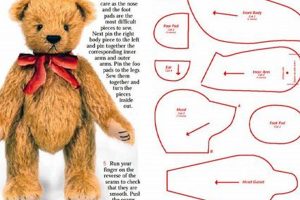

Sewing templates for creating stuffed teddy bears, typically printed or drafted on paper or fabric, provide precise dimensions and shapes for each component, such as the head, body, limbs, and ears. These templates ensure consistent results and simplify the construction process for both novice and experienced creators. A well-designed template often includes markings for seam allowances, embroidery placement, and joint articulation points.

Utilizing these guides offers numerous advantages. They ensure accurate proportions and symmetry, reducing the likelihood of errors during assembly. This precision leads to a higher quality finished product with a professional appearance. Furthermore, templates provide a foundation for customization. Creators can adapt existing designs or develop entirely new variations by altering the shape, size, or features of the template components. Historically, these guides have been instrumental in preserving traditional designs and facilitating the transmission of crafting skills across generations. From simple, classic forms to intricate, character-driven creations, these blueprints provide the essential framework for bringing beloved stuffed companions to life.

This discussion will further examine several key aspects of these fundamental tools, including different types of templates, material selection, adaptation techniques, and resources for locating or creating original designs. A comprehensive understanding of these elements will empower both aspiring and established craftspeople to elevate their creations and explore the boundless creative potential within this timeless craft.

Tips for Utilizing Teddy Bear Sewing Templates

Careful consideration of several key aspects will maximize the effectiveness and utility of sewing templates when crafting stuffed bears. Attention to detail during material selection, pattern preparation, and construction techniques contributes significantly to the quality and longevity of the finished product.

Tip 1: Pattern Selection: Choose a template appropriate for one’s skill level. Simpler designs are recommended for beginners, while more complex patterns offer challenges for experienced crafters.

Tip 2: Material Choice: Select durable, high-quality fabrics like mohair, alpaca, or synthetic plush for the exterior. Sturdy cotton or linen works well for pattern pieces intended for internal components.

Tip 3: Precise Cutting: Cut fabric pieces accurately along pattern lines, ensuring proper alignment and avoiding jagged edges. Sharp scissors and rotary cutters enhance precision.

Tip 4: Marking Techniques: Transfer all markings from the template to the fabric using tailor’s chalk, disappearing ink, or small notches. Accurate marking ensures correct alignment during assembly.

Tip 5: Seam Allowances: Adhere to the seam allowance specified in the pattern instructions. Consistent seam allowances are crucial for proper fit and a professional finish.

Tip 6: Joint Articulation: Employ appropriate jointing methods, such as cotter pin joints or disc joints, for movable limbs. Secure joints tightly to prevent loosening over time.

Tip 7: Stuffing Techniques: Distribute stuffing evenly throughout the bear, paying attention to firm packing in the head and limbs. Appropriate stuffing density ensures a pleasing shape and tactile quality.

Adherence to these guidelines will significantly enhance the quality and durability of handcrafted bears, allowing creators to achieve professional results while minimizing potential frustrations during the construction process. Successful implementation of these techniques cultivates a deeper understanding of the craft and fosters greater creative exploration.

By understanding the intricacies of pattern selection, material choice, and construction techniques, individuals can transform simple materials into cherished heirlooms.

1. Template Accuracy

Template accuracy represents a cornerstone of successful teddy bear creation. Precise templates directly influence the final product’s quality, impacting proportions, symmetry, and overall aesthetic appeal. A thorough understanding of this critical element allows crafters to achieve professional results and avoid common construction pitfalls.

- Dimensional Precision

Accurate measurements on the template translate to proper proportions in the finished bear. Discrepancies in template dimensions, even minor ones, can lead to noticeable asymmetries or ill-fitting components. For instance, a head template that is too narrow may result in a finished bear with a disproportionately small head. Careful attention to dimensional precision throughout the template ensures a harmonious final product.

- Shape Integrity

Templates not only dictate size but also shape. Curves, angles, and unique design features rely on accurate template shapes for proper execution. A poorly drafted curve on an ear template, for example, could lead to misshapen ears on the finished bear. Maintaining shape integrity within the template ensures the intended design is faithfully reproduced in the final piece.

- Seam Allowance Consistency

Templates often incorporate designated seam allowances. Consistent seam allowances throughout the template are essential for proper component alignment and assembly. Inconsistent seam allowances can cause difficulties in joining pieces, resulting in a poorly constructed or distorted final product. Uniform seam allowances, clearly marked on the template, streamline the assembly process and contribute to a professional finish.

- Notch and Marking Clarity

Notches and markings on templates serve as critical guides for alignment, embroidery placement, and joint articulation. Clear, accurately placed markings facilitate precise assembly and ensure design elements are positioned correctly. For instance, unclear markings for eye placement can result in asymmetrical or misplaced eyes on the finished bear. Precise notches and markings contribute significantly to the accuracy and overall quality of the final creation.

These facets of template accuracy underscore the crucial role precise templates play in crafting well-proportioned, aesthetically pleasing teddy bears. Attention to detail in template creation, including accurate dimensions, well-defined shapes, consistent seam allowances, and clear markings, ensures successful project completion and allows crafters to realize their design vision with precision and confidence.

2. Seam Allowances

Seam allowances, the fabric width between the raw edge and the stitching line, constitute a critical element within teddy bear making patterns. Proper seam allowance selection and execution directly impact the final product’s structural integrity, aesthetic appeal, and overall durability. A comprehensive understanding of seam allowance principles allows crafters to achieve professional results and avoid construction challenges.

- Pattern Integrity

Designated seam allowances, typically specified within the pattern instructions, ensure accurate component assembly. Adhering to these specifications maintains the intended proportions and shape of the finished bear. Deviating from designated seam allowances can lead to misaligned components, distorted shapes, and an overall compromised design. Consistent adherence to pattern-specified seam allowances ensures the integrity of the original design.

- Durability and Strength

Adequate seam allowances contribute significantly to the finished bear’s strength and durability. Sufficient fabric width beyond the stitching line provides resistance against seam ripping or fraying under stress. Narrow seam allowances increase the risk of seam failure, particularly in high-stress areas like joints or frequently handled areas. Ample seam allowances provide a robust foundation for long-lasting construction.

- Ease of Construction

Appropriate seam allowances facilitate the construction process itself. Sufficient fabric width provides ample material for handling during stitching, reducing the likelihood of accidental slippage or misalignment. Excessively narrow seam allowances complicate the joining process, increasing the risk of errors. Well-chosen seam allowances contribute to a smoother, more efficient assembly process.

- Aesthetic Impact

While primarily a structural element, seam allowances also contribute to the finished bear’s aesthetic quality. Consistent, well-executed seam allowances create a neat, professional appearance. Uneven or excessively wide seam allowances detract from the overall aesthetic appeal. Careful attention to seam allowance consistency enhances the visual appeal and perceived craftsmanship of the finished product.

Precise execution of seam allowances represents a fundamental skill in teddy bear creation. Understanding the interplay between seam allowances, pattern accuracy, and construction techniques allows crafters to produce durable, aesthetically pleasing, and structurally sound teddy bears. Careful consideration and precise implementation of seam allowance guidelines contribute significantly to the overall success and longevity of each handcrafted creation.

3. Fabric Choice

Fabric selection significantly influences the final characteristics of a teddy bear crafted from a pattern. The interplay between fabric properties and pattern design constitutes a crucial consideration in achieving the desired aesthetic, tactile quality, and overall durability. Specific fabric characteristics, including pile length, density, and drape, directly impact the pattern’s translation into a three-dimensional form.

For instance, a dense, short-pile plush fabric lends itself well to patterns featuring intricate details and defined shapes. The fabric’s inherent structure holds its form, allowing fine details from the pattern to be accurately represented in the finished bear. Conversely, a long-pile, loosely woven fabric may obscure finer details within the pattern, resulting in a softer, less defined final product. This type of fabric might be more suitable for simpler patterns emphasizing texture and overall shape rather than intricate features. Drape, the way fabric falls or hangs, also impacts how a pattern translates into a three-dimensional form. A stiff fabric with minimal drape may require pattern adjustments to accommodate its rigidity, while a fabric with significant drape may necessitate careful consideration of how the fabric will fold and gather during construction.

Understanding the relationship between fabric choice and pattern design empowers crafters to make informed decisions that align with their creative vision. Careful consideration of fabric properties in relation to pattern complexity ensures the successful realization of the intended design. This understanding enhances both the creative process and the quality of the finished product, resulting in a well-crafted, enduring teddy bear that reflects the crafter’s skill and artistic intent.

4. Jointing Methods

Jointing methods represent a critical aspect of teddy bear construction, directly impacting the final product’s poseability, durability, and overall character. The chosen jointing method interacts intimately with the teddy bear making pattern, influencing both the design process and the final articulation of the finished piece. Understanding the nuances of various jointing techniques allows crafters to select the most appropriate method for achieving the desired range of motion and structural integrity.

- Cotter Pin Joints

Cotter pin joints, a traditional method, offer robust articulation and secure limb attachment. These joints utilize cotter pins inserted through pre-drilled holes in the limbs and body components, secured with washers to prevent loosening. Patterns designed for cotter pin joints often incorporate specific markings to indicate optimal joint placement and hole sizes. This method provides firm, stable joints suitable for bears intended for frequent handling and posing.

- Disc Joints

Disc joints provide a smoother range of motion compared to cotter pin joints. These joints utilize interlocking discs, typically made of plastic or cardboard, to connect limbs to the body. Patterns employing disc joints require precise alignment of corresponding components to ensure proper joint function. Disc joints lend themselves to creating bears with more fluid, lifelike movement.

- Button Joints

Button joints, often used for smaller bears or miniature creations, offer a simpler method of articulation. These joints involve stitching buttons directly onto the body, with corresponding loops or fabric ties on the limbs for attachment. Patterns utilizing button joints prioritize simplicity and ease of construction. This method, while less robust than cotter pin or disc joints, offers a cost-effective solution for achieving basic poseability.

- T-Joint Construction

The T-joint method, commonly employed for traditional teddy bear designs, involves shaping and stitching the limbs and body components to create interlocking “T” shapes at the joints. Patterns using this method require precise cutting and stitching to achieve a secure and aesthetically pleasing joint. T-joints contribute to the classic, timeless appeal of traditional teddy bears.

The selection of a jointing method directly influences the pattern design, assembly process, and final articulation of the teddy bear. Understanding the advantages and limitations of each method allows crafters to make informed decisions that align with their project goals, ensuring a well-crafted, enduring companion that embodies the desired character and poseability. The interplay between jointing methods and pattern design underscores the intricate relationship between technical execution and artistic expression within the craft of teddy bear making.

5. Embroidery Placement

Embroidery placement constitutes a critical design element within teddy bear making patterns, significantly impacting the final product’s character and expressiveness. Precisely positioned embroidery details, guided by the pattern, breathe life into the creation, conveying emotions and establishing the bear’s unique personality. The interplay between pattern markings and embroidery placement requires careful consideration, influencing both the design process and the final aesthetic outcome.

- Facial Features

Accurate embroidery placement for facial features, such as eyes, nose, and mouth, plays a pivotal role in establishing the bear’s character. Patterns often incorporate specific markings to guide the placement of these crucial details, ensuring symmetry and achieving the desired expression. Variations in eye placement, for example, can convey a range of emotions, from joy to sadness or even mischief. Precise execution of these details transforms a simple stuffed form into a character-rich companion.

- Expressive Details

Beyond basic facial features, embroidery can add further expressive details, such as eyebrows, eyelashes, or even small beauty marks. These subtle additions, guided by the pattern, enhance the bear’s personality and contribute to its overall charm. For instance, arched eyebrows might suggest a curious or inquisitive nature, while long, sweeping eyelashes might add a touch of elegance. Such details, while seemingly minor, significantly impact the bear’s perceived character.

- Decorative Elements

Embroidery can also introduce decorative elements unrelated to facial features, such as floral patterns, geometric designs, or personalized motifs. These embellishments, positioned according to the pattern, enhance the bear’s aesthetic appeal and can reflect the crafter’s individual style or the recipient’s preferences. A delicately embroidered floral pattern on the bear’s chest, for example, adds a touch of whimsy, while a personalized monogram adds a sentimental touch. Such decorative elements transform the bear into a unique, personalized creation.

- Pattern Integration

Effective embroidery placement harmonizes with the overall pattern design. The embroidery should complement the bear’s shape, proportions, and intended character. For instance, a bold, geometric embroidery pattern might clash with a simple, classic bear design, while a delicate floral motif might enhance its charm. Careful consideration of the interplay between embroidery placement and the overall pattern design ensures a cohesive and aesthetically pleasing final product.

Successful embroidery placement relies on precise execution guided by the teddy bear making pattern. This interplay between pattern and embroidery transforms simple stitches into expressive features and decorative elements, imbuing the finished bear with personality and charm. A thorough understanding of embroidery placement techniques, combined with careful attention to pattern markings, allows crafters to create unique, character-rich companions that transcend mere toys and become cherished works of art.

Frequently Asked Questions

This section addresses common inquiries regarding teddy bear sewing templates, providing concise and informative responses to facilitate a comprehensive understanding of their utilization and significance.

Question 1: What are the essential tools required for utilizing teddy bear sewing templates effectively?

Essential tools include sharp fabric scissors or a rotary cutter, pins for securing pattern pieces to fabric, a marking tool such as tailor’s chalk or disappearing ink, a sewing machine or needle and thread for hand-sewing, and stuffing material such as polyester fiberfill.

Question 2: Where can suitable templates for crafting teddy bears be obtained?

Templates can be acquired from various sources, including craft books, online marketplaces specializing in sewing patterns, dedicated teddy bear supply stores, and independent pattern designers. Numerous free resources are also available online.

Question 3: How can template dimensions be adjusted to create bears of varying sizes?

Template dimensions can be adjusted using a photocopier or scanner to enlarge or reduce the pattern pieces proportionally. Specialized software designed for pattern manipulation also offers precise scaling capabilities. Careful recalculation of seam allowances may be necessary after resizing.

Question 4: What types of fabrics are most suitable for constructing teddy bears from patterns?

Suitable fabrics include mohair, alpaca, and synthetic plush for the exterior. Durable cotton or linen works well for internal components. Fabric selection should consider desired texture, durability, and aesthetic qualities.

Question 5: What are the key considerations when selecting jointing methods for a teddy bear project?

Key considerations include desired poseability, the bear’s intended use (e.g., display versus play), and the crafter’s skill level. Common jointing methods include cotter pins, disc joints, button joints, and T-joints, each offering varying levels of complexity and articulation.

Question 6: How can seam allowances be adjusted on a teddy bear making pattern?

Seam allowances can be adjusted by redrawing the pattern pieces with the desired seam allowance width. Adding or subtracting the desired adjustment from the original cutting lines allows for customization. Careful marking of the new seam lines ensures accurate construction.

Careful selection and utilization of templates, combined with an understanding of material properties and construction techniques, are essential for successful teddy bear creation. These combined factors influence the final product’s quality, durability, and overall aesthetic appeal.

Further sections will explore advanced techniques and specialized resources for those seeking to refine their teddy bear crafting skills and expand their creative repertoire.

Conclusion

Teddy bear making patterns provide the foundational blueprint for crafting these cherished companions. Exploration of template accuracy, seam allowance considerations, fabric selection, jointing methods, and embroidery placement reveals the intricate interplay between pattern and finished product. Each element contributes significantly to the bear’s final form, character, and durability, highlighting the essential role of well-drafted patterns in successful teddy bear creation. From initial design concept to the final stitches, adherence to pattern guidelines ensures a well-crafted, enduring keepsake.

The enduring appeal of handcrafted teddy bears underscores the significance of these guiding patterns. They represent more than mere instructions; they embody a legacy of craftsmanship and creativity. Continued exploration and refinement of pattern design techniques will further enrich this timeless craft, ensuring future generations can experience the joy of bringing these beloved companions to life.