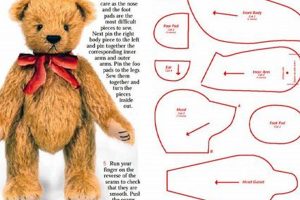

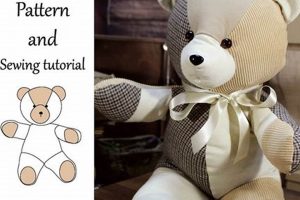

Creating stuffed toys from fabric involves using predefined designs, often printed or drafted, to guide the cutting and assembly of material. These designs, specifically for constructing teddy bears, dictate the shape, size, and features of the final product. An example includes designs for a classic teddy bear with jointed limbs or a more contemporary, less articulated style.

This craft offers a tangible, creative outlet, resulting in unique, handmade toys. Beyond the personal satisfaction of creation, it provides an opportunity to personalize gifts or create cherished heirlooms. Historically, homemade toys served as both entertainment and comfort, reflecting the maker’s skill and care. This tradition continues to resonate with crafters today, who find joy in creating personalized, handcrafted items.

Further exploration of this topic will delve into the selection of appropriate materials, tools, and techniques required for successful toy creation, from initial design choice to final assembly and finishing touches.

Tips for Crafting Teddy Bears

Successful teddy bear construction requires attention to detail and adherence to best practices. The following tips offer guidance for achieving professional results.

Tip 1: Accurate Pattern Cutting: Precise cutting ensures proper alignment and fit of the fabric pieces. Sharp scissors and careful adherence to pattern markings are essential.

Tip 2: Appropriate Fabric Selection: Durable, soft fabrics like mohair, plush, or fleece are ideal for creating teddy bears. Consider the desired texture and appearance when selecting materials.

Tip 3: Secure Seam Allowance: Maintaining a consistent seam allowance, as specified in the pattern, ensures the final product matches the intended dimensions and proportions.

Tip 4: Sturdy Joint Mechanisms: Securely attached joints, whether disc-jointed, cotter-pinned, or sewn, are crucial for durability and poseability.

Tip 5: Careful Stuffing Technique: Even stuffing distribution prevents lumps and ensures a smooth, professional finish. Using a stuffing tool can assist with filling hard-to-reach areas.

Tip 6: Securely Fastened Features: Eyes, noses, and other embellishments should be attached securely to withstand handling and play. Consider embroidery or specialized safety features for children’s toys.

Tip 7: Invisible Stitching Techniques: Employing ladder stitch or other hidden stitching methods creates a seamless, polished appearance.

Adherence to these guidelines will result in a well-crafted, durable, and aesthetically pleasing teddy bear. These techniques contribute to the creation of a treasured keepsake.

By following these tips, crafters can achieve professional results and ensure the longevity of their handmade creations.

1. Pattern Selection

Pattern selection represents a foundational element in crafting teddy bears. The chosen design dictates the final form, proportions, and complexity of the finished piece, influencing construction techniques and material requirements. Careful consideration of available options is crucial for achieving desired results.

- Complexity Level

Patterns range from simple designs suitable for beginners to intricate, articulated designs requiring advanced sewing skills. A simple pattern might involve basic shapes and minimal seams, ideal for novice crafters. Conversely, a complex pattern might incorporate intricate jointing mechanisms and detailed features, posing a greater challenge. Pattern complexity directly impacts construction time and required skill level.

- Style and Aesthetics

Pattern selection dictates the overall aesthetic of the teddy bear. Options range from classic, jointed bears reminiscent of traditional designs to more contemporary, stylized interpretations. Some patterns emphasize realism, while others embrace whimsical or abstract forms. Choosing a pattern aligned with the desired aesthetic ensures a satisfying outcome.

- Size and Scale

Patterns are available in a variety of sizes, from miniature bears designed for collectibles to large, huggable companions. The chosen size influences material requirements and construction techniques. Smaller bears demand finer materials and precise stitching, while larger bears benefit from more robust fabrics and construction methods. Scale considerations must align with the intended purpose and available resources.

- Construction Techniques

Different patterns utilize varying construction techniques, influencing the final product’s articulation and durability. Some patterns employ traditional jointing methods, allowing for poseable limbs, while others prioritize a simpler, less articulated design. The chosen construction technique dictates the necessary tools and materials, impacting the overall complexity of the project. For instance, a pattern featuring gussetted limbs necessitates different sewing skills compared to a pattern with simpler, sewn-on limbs.

Careful consideration of these facets within pattern selection ensures alignment between the crafter’s skill level, available resources, and desired outcome. This foundational step significantly influences the final teddy bear’s appearance, durability, and overall character.

2. Fabric Choice

Fabric selection significantly impacts the final aesthetic, durability, and tactile qualities of a handcrafted teddy bear. Appropriate fabric choice complements the chosen pattern and intended purpose, influencing the construction process and overall success of the project. Consideration of various fabric properties is crucial for achieving desired results.

- Pile and Texture

Pile refers to the raised fibers on a fabric’s surface, contributing to its texture and appearance. Mohair, a popular choice for traditional teddy bears, possesses a distinctive, luxurious pile. Shorter pile fabrics, like fleece or plush, offer a smoother, softer texture. The chosen pile and texture influence the bear’s overall appearance, impacting how light interacts with the surface and affecting perceived softness.

- Durability and Wear

Fabric durability dictates the bear’s ability to withstand handling and play. Tightly woven fabrics with strong fibers, like canvas or denim, offer greater resistance to wear and tear. Conversely, delicate fabrics, like silk or linen, are less suited for frequent handling. Durability considerations are particularly important for children’s toys, which experience more rigorous use. Choosing appropriate fabric ensures longevity and maintains the bear’s appearance over time.

- Drape and Structure

Drape refers to how fabric falls and folds. Fabrics with a fluid drape, like rayon or silk, conform easily to curves, while stiffer fabrics, like felt or upholstery fabric, maintain their shape. The chosen drape influences the bear’s overall form and how the pattern translates into a three-dimensional object. For example, a stiffer fabric might be preferred for a bear with distinct, well-defined features.

- Color and Pattern

Fabric color and pattern contribute significantly to the bear’s personality and aesthetic. Solid colors offer a classic, versatile option, while patterned fabrics introduce visual interest and complexity. Color choices can evoke specific emotions or themes. For example, pastel shades might create a soft, gentle feel, while vibrant colors might convey energy and playfulness. Careful selection of color and pattern enhances the bear’s overall design and character.

The interplay between these fabric properties and the chosen pattern significantly influences the final teddy bear. A durable, tightly woven fabric complements a pattern designed for robust play, while a luxurious, long-pile fabric enhances a pattern intended for display or gentle handling. Harmonizing fabric choice with pattern selection ensures a successful outcome and a cherished finished product.

3. Cutting Accuracy

Cutting accuracy represents a critical factor in successful teddy bear construction. Precise cutting, following pattern markings meticulously, directly influences the final product’s structural integrity, symmetry, and overall appearance. Deviations from prescribed cutting lines can result in misaligned seams, distorted shapes, and an unprofessional finish. For instance, inaccurately cut fabric pieces for a bear’s head can lead to asymmetry, affecting the placement of facial features and overall aesthetic balance. Similarly, imprecise cutting of limb components can compromise joint articulation and overall poseability.

The relationship between cutting accuracy and pattern complexity is significant. Intricate patterns, featuring numerous small pieces or curved seams, demand greater precision. Minor cutting errors in these complex designs can compound during assembly, leading to noticeable discrepancies in the final product. Conversely, simpler patterns, with larger, more straightforward pieces, offer greater tolerance for minor cutting inaccuracies. However, even in simpler designs, consistent adherence to cutting lines remains essential for achieving a polished, professional result. Employing sharp scissors and appropriate cutting surfaces, such as a rotary cutter and cutting mat, contributes significantly to improved cutting accuracy.

Precise cutting ensures proper alignment of fabric pieces during assembly, facilitating seamless seam construction and contributing to the structural integrity of the finished bear. This accuracy forms the foundation for a well-crafted, durable, and aesthetically pleasing result. Challenges in achieving cutting accuracy can arise from factors such as fabric type, pattern intricacy, and available tools. Overcoming these challenges requires careful attention to detail, practice, and the utilization of appropriate techniques. Mastering cutting accuracy elevates the overall quality and professionalism of the finished teddy bear, transforming it from a simple craft project into a cherished keepsake.

4. Seam Construction

Seam construction represents a pivotal element in teddy bear creation, directly influencing the final product’s durability, aesthetics, and structural integrity. Seam choice and execution significantly impact the bear’s ability to withstand handling, maintain its shape, and exhibit a polished, professional appearance. Different seam types offer varying levels of strength and visual appeal, impacting the overall perception of quality and craftsmanship. For example, a ladder stitch, employed for closing openings and attaching limbs, creates a nearly invisible seam, enhancing the bear’s finished look. Conversely, stronger seams, like French seams or flat-felled seams, provide enhanced durability, particularly beneficial for areas subject to stress, such as joints or frequently handled areas. A poorly executed seam, regardless of type, can compromise the bear’s structural integrity, leading to seam separation, stuffing leakage, and diminished aesthetic appeal.

The relationship between seam construction and pattern design is integral. Pattern instructions typically specify recommended seam types and techniques tailored to the specific design. Adhering to these recommendations ensures structural soundness and facilitates the intended shaping and articulation of the bear. For instance, a pattern designed for a jointed bear might specify reinforced seams at joint locations to accommodate the stress of movement. Ignoring these recommendations can compromise the joint’s stability and longevity. Furthermore, seam allowance, a critical element dictated by the pattern, directly influences the final dimensions and proportions of the bear. Inconsistent seam allowances can lead to mismatched pieces, distorted shapes, and an unprofessional finish. Proper seam allowance adherence ensures accurate assembly and contributes to a polished final product.

Mastering various seam construction techniques empowers crafters to select the most appropriate method for each stage of the teddy bear creation process. Strong, well-executed seams contribute significantly to the bear’s longevity, resilience, and overall quality. Challenges in seam construction often arise from fabric choice, pattern complexity, and individual skill level. Addressing these challenges through practice and attention to detail enhances craftsmanship and elevates the perceived value of the finished teddy bear. A well-constructed seam not only fulfills a functional role but also serves as a testament to the crafter’s skill and dedication, transforming a simple toy into a cherished heirloom.

5. Stuffing Technique

Stuffing technique constitutes a critical stage in teddy bear construction, significantly influencing the final product’s shape, feel, and overall durability. Proper stuffing technique transforms a two-dimensional sewn form into a three-dimensional, tactile object. This process directly impacts the bear’s aesthetic appeal, cuddle factor, and ability to maintain its intended form over time. The interplay between stuffing technique and pattern design is crucial, as the pattern often dictates specific stuffing requirements for achieving desired results. Understanding and executing appropriate stuffing techniques are essential for achieving a professional, well-crafted teddy bear.

- Stuffing Material Selection

Stuffing material choice significantly influences the bear’s weight, texture, and resilience. Options range from traditional polyester fiberfill, offering a soft, lightweight feel, to wool or cotton stuffing, providing a denser, more traditional feel. Specialized stuffing materials, such as weighted pellets, can be incorporated to add weight and enhance poseability. Material selection depends on the desired tactile qualities and intended purpose of the bear. For example, a bear intended for a child might benefit from hypoallergenic polyester fiberfill, while a collectible bear might utilize a more traditional wool or kapok stuffing.

- Stuffing Density and Distribution

Achieving uniform stuffing density and distribution is crucial for preventing lumps, maintaining symmetry, and ensuring the bear holds its shape. Overstuffing can create a rigid, unyielding feel, while understuffing can result in a floppy, less defined form. Careful attention must be paid to evenly distributing the stuffing throughout the bear’s body, paying particular attention to extremities and contoured areas. Using specialized stuffing tools can assist in achieving uniform density and reaching difficult-to-access areas. Proper density and distribution enhance the bear’s aesthetic appeal and contribute to its longevity.

- Shaping and Contouring

Skillful stuffing technique involves shaping and contouring the bear’s body during the stuffing process. This involves manipulating the stuffing material to create desired curves, angles, and definition. For example, firmly packing stuffing into the head creates a well-defined muzzle and facial structure, while strategically placing stuffing in the limbs enhances their shape and poseability. This process requires tactile sensitivity and an understanding of the underlying form dictated by the pattern. Effective shaping and contouring transform a simple stuffed form into a characterful, aesthetically pleasing creation.

- Closure and Finishing

The final stage of stuffing involves securely closing the stuffing opening, typically using a ladder stitch or other invisible stitching method. A properly closed opening prevents stuffing leakage and maintains the bear’s finished appearance. This step requires careful attention to detail and precise stitching technique to create a seamless, almost invisible closure. The closure method should complement the chosen fabric and overall aesthetic of the bear, contributing to a polished, professional finish.

The interplay between these facets of stuffing technique and the broader context of teddy bear pattern sewing is essential for achieving a well-crafted, durable, and aesthetically pleasing final product. Mastering stuffing technique elevates the craft of teddy bear making, transforming simple materials into cherished keepsakes. Careful attention to stuffing material selection, density, distribution, shaping, and closure techniques ensures a finished product that reflects both the crafter’s skill and the inherent charm of a handcrafted teddy bear.

6. Finishing Details

Finishing details represent the culmination of the teddy bear creation process, transforming a sewn and stuffed form into a characterful, finished piece. These details, while seemingly minor, significantly impact the bear’s overall aesthetic, perceived quality, and emotional resonance. Careful consideration and execution of finishing details elevate the craft of teddy bear pattern sewing, imbuing the finished product with personality and charm. From facial features to embellishments, each detail contributes to the bear’s unique identity and perceived value.

- Facial Features

Facial features, including eyes, nose, and mouth, imbue the teddy bear with personality and expressiveness. Material choices range from traditional glass eyes, offering a classic, lifelike appearance, to embroidered or painted features, providing a softer, more stylized aesthetic. Secure attachment of facial features is crucial for safety and longevity. Precise placement dictates the bear’s expression, ranging from cheerful and playful to contemplative and endearing. For example, slightly upturned embroidered eyebrows can convey a sense of innocence, while strategically placed glass eyes can create a sense of engagement and personality.

- Embellishments

Embellishments, such as ribbons, bows, clothing, or accessories, enhance the teddy bear’s personality and visual appeal. These additions can reflect specific themes, occasions, or personal preferences. A hand-knitted scarf might evoke a sense of warmth and comfort, while a miniature top hat might add a touch of whimsy and sophistication. Embellishments offer opportunities for personalization and creative expression, transforming the bear into a unique, individualized creation. Careful selection and application of embellishments enhance the bear’s overall design and narrative.

- Joint Articulation

Joint articulation, while technically a structural element, contributes significantly to the finished bear’s poseability and interactive potential. Securely fastened and properly functioning joints allow for dynamic posing, enhancing the bear’s playability and expressive capabilities. Various jointing methods, including disc joints, cotter pin joints, and button joints, offer varying degrees of movement and durability. Smooth, well-functioning joints enhance the bear’s tactile appeal and encourage interaction.

- Final Grooming

Final grooming, often overlooked, represents the last stage in perfecting the teddy bear’s appearance. This involves brushing and shaping the fur or pile, trimming any loose threads, and ensuring all seams and attachments are secure and visually appealing. This meticulous attention to detail enhances the bear’s overall presentation and perceived quality. Final grooming elevates the bear from a crafted object to a polished, finished piece, ready to be cherished and enjoyed.

The culmination of these finishing details elevates teddy bear pattern sewing from a technical process to an art form. Each detail contributes to the bear’s unique character, enhancing its aesthetic appeal and emotional resonance. These seemingly small additions transform a simple sewn object into a cherished companion, reflecting the crafter’s skill and imbuing the finished product with enduring value.

Frequently Asked Questions

This section addresses common inquiries regarding the craft of creating teddy bears from patterns.

Question 1: What type of fabric is most suitable for constructing teddy bears?

Mohair plush, alpaca, and synthetic furs are frequently chosen for their softness and durability. Fabric selection depends on the desired aesthetic and intended usage. Densely woven fabrics offer greater durability, while softer, plusher fabrics enhance tactile appeal.

Question 2: What are the essential tools required for this craft?

Essential tools include sharp fabric scissors, pins, needles, strong thread, a seam ripper, and stuffing. Specialized tools, such as a stuffing tool or curved needles, can facilitate specific tasks and enhance precision.

Question 3: What are common challenges encountered during teddy bear construction, and how can these be addressed?

Challenges may include accurately cutting intricate pattern pieces, achieving uniform stuffing distribution, and securely attaching joints. Careful pattern interpretation, practice, and the utilization of appropriate tools mitigate these difficulties. Online tutorials and crafting communities offer valuable resources for troubleshooting specific issues.

Question 4: Where can suitable patterns be obtained?

Patterns are available from various sources, including independent designers, craft stores, and online marketplaces. Selection depends on desired style, complexity, and skill level.

Question 5: How can the longevity of a handmade teddy bear be ensured?

Employing durable materials, reinforced seams, and secure joint attachments enhances longevity. Gentle handling and appropriate cleaning methods further contribute to the preservation of the finished product.

Question 6: What safety considerations are relevant, particularly for children’s toys?

Safety considerations include using child-safe materials, securely attaching all components, and avoiding small parts that could pose choking hazards. Embroidered or painted facial features are often preferred over potentially detachable plastic or glass elements for toys intended for young children. Adherence to relevant safety standards and regulations ensures the well-being of the recipient.

Careful consideration of these frequently asked questions equips individuals with the knowledge and resources necessary for successful teddy bear creation. Addressing these common concerns facilitates a smoother crafting experience and contributes to the creation of cherished, well-crafted keepsakes.

Further resources and tutorials are available for those seeking in-depth guidance on specific techniques and pattern variations.

Conclusion

Construction of teddy bears from patterns offers a tangible connection to a rich crafting legacy. This practice involves a multifaceted process encompassing pattern selection, material acquisition, precise cutting, meticulous seam construction, considered stuffing techniques, and thoughtful application of finishing details. Each stage contributes significantly to the final product’s quality, durability, and aesthetic appeal. Understanding the interplay between these elements is crucial for achieving desired outcomes, whether aiming for heirloom-quality creations or engaging in a fulfilling creative pursuit.

The enduring appeal of handcrafted teddy bears lies not solely in their physical form but also in the imbued narrative of creation. They represent tangible expressions of creativity, skill, and care. This enduring craft continues to offer opportunities for personal expression, skill development, and the creation of cherished objects that transcend mere playthings, embodying a timeless connection between maker and creation.